Paintable Mold Release | ReleaSys™ 7800

$94.86 – $161.67

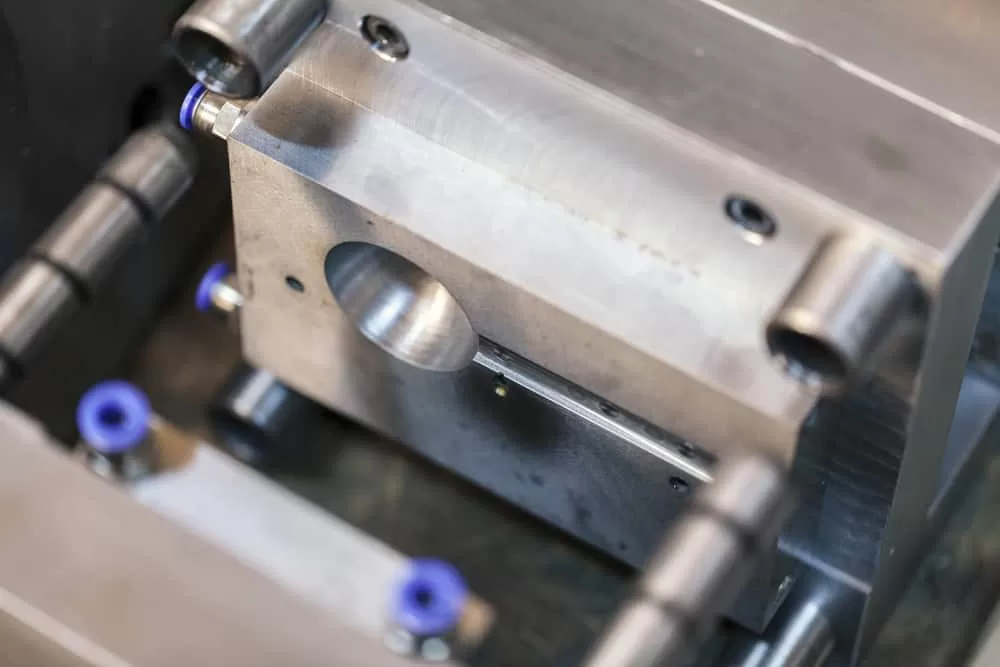

100% Paintable mold release agent system designed to provide superior mold release for all Polyurethane, Plastics, and Rubbers. Molded parts can be painted, plated, hot-stamped, bonded, labelled or otherwise decorated without the need for time consuming cleaning or washing.

- Paintable Mold Release, Zero Transfer

- Ideal for Polyurethane, Plastic, and Rubber

- Ideal for complex molds and stubborn parts

- Elimination of “fish eyes” and post-molding cleaning

- Optimal pigment transfer and color appearance

Paintable Mold Release | ReleaSys™ 7800

100% Paintable, Mold Release Agent; Highly Effective for Polyurethane, Plastic, and Rubber

ReleaSys™ 7800 Paintable Mold Release is a high performance, thin film release agent designed to offer superior slip and release ease. Miller-Stephenson’s advanced chemistry provides a release agent which allows molded parts to be painted, plated, hot stamped, bonded, labelled or otherwise decorated without the need for time consuming post molding cleaning. ReleaSys 7800 adheres strongly to mold surfaces providing extended release performance with no transfer or oily residue. The applied paintable release agent has excellent lubricity, this facilitates resins, plastics, and other polymers to easily flow and fill all molding crevices. This greatly improves part quality, reliability and increases ease of release. This product is also an ideal complement to other ReleaSys products such as ReleaSys™ MOLD SEALER, and ShieldSys™ MX120, When used in unison, ReleaSys™ 7800 paintable mold release provides increased surface slip, release ease, and resin flow out.

Benefits of Paintable Mold Release Agents

- Ideal of Polyurethane, Plastic, and Rubber manufacturers

- Allows molded parts to be painted, hot stamped. bonded, decorated, etc. without cleaning

- Bonds to mold surfaces, forming a durable mold release film

- Compatible with a range of moldable materials

- Elimination of fish-eyes, surface defects, or surface staining

- Extended service life of flexible molds

- Seals micro porosity and freshly repaired molds

- Optimal pigment transfer and color appearance

Applications of Paintable Mold Release Systems

ReleaSys 7800 is a high performance mold release system designed to provide excellent release and improve part quality without messy transfer or oily parts. The proprietary coating binds strongly to mold surfaces eliminating transfer while enhancing resin flow out. The coating is particularly effective on Polyurethanes, Plastics, and Rubber substrates and offers high heat stability beyond 650 °F. Unlike tradtional silicone based release coatings, ReleaSys 7800 Paintable mold release combines high release, zero transfer, and improved surface quality. Applications include:

- All Polyurethanes, including cast elastomers, rigid and flexible foams, and integral skin

- Plastics – specifically for high temperature injection systems – excellent resin flow out, zero staining or transfer

- Rubbers – All rubbers compounds and better release than traditional fluoropolymers

Superior Release Agent Systems & Unmatched Customer Service

For assistance with proper application, storage, or general assistance please see the links below or call our tech service line. Miller-Stephenson has a team of release experts ready to help you. Our experience and relationship with molding operations, both large and small, provide our technical team with a dynamic perspectives and ‘real-world’ practicality. Our staff hold the skills and experience needed to make sure your molding operation is cost effective, efficient, and most importantly, safe. To read more about the science and development that goes into developing our ReleaSys 7800 Paintable Mold Release Systems following the attached link

50+ years of Industry Expertise at your service

The ReleaSys™ brand of products are respected around the world for quality and reliability. When you purchase a Miller-Stephenson ReleaSys mold release agent you not only get industry leading products, but access to our many years of direct production floor experience. We understand your production issues and can help you optimize your mold preparation, maintenance and release processes to improve your bottom line. Our product expertise in polyurethane mold release agents ensure we recommend the right product for your specific challenges – guaranteed.

For help with application or troubleshooting concerns while using ReleaSys.

Click here for information, Which mold release agent is right for you

ReleaSys product line and Applications – our most helpful article for selecting the best product for your needs

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

Primary Polymer:……Proprietary Polymer

Appearance:…………Straw Liquid

Odor:…………………None

Specific Gravity:…….0.66 g/mL @ 25°C

Flash Point…………..<30 °C

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Bulk Sizes | Quart, 1 Gallon, 5 Gallon |

Recommended Application Procedure:

- Clean mold surface thoroughly. Mechanical cleaning such as bead media blasting, followed by chemical cleaning, provides the best surface for application. Removal of all previous mold release agent and contamination is critical.

- ReleaSys™ 7800 can be applied by any spray equipment that can produce fine atomization and deposit a uniform, thin film. Apply light coats, approximately 8-10 inches from the surface. Surface wiping can be done as well, no additional polishing is required.

- ReleaSys™ 7800 is a concentrated product. It can be used as is for release of complex molds or diluted to a final working concentration. Dilution is ideally performed with low flash point solvents.

- Allow ReleaSys™ 7800 to dry completely. Multiple light coats can be applied, and will increase durability and protection. Typically 1-3 coats is sufficient.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

Gallon, 55 Gallon Drum, 275 Gallon Tote

ReleaSys 78 – Aerosol version of ReleaSys 7800

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.