Non Stick Release Coating | ShieldSys™ MX120

$663.41 – $842.69

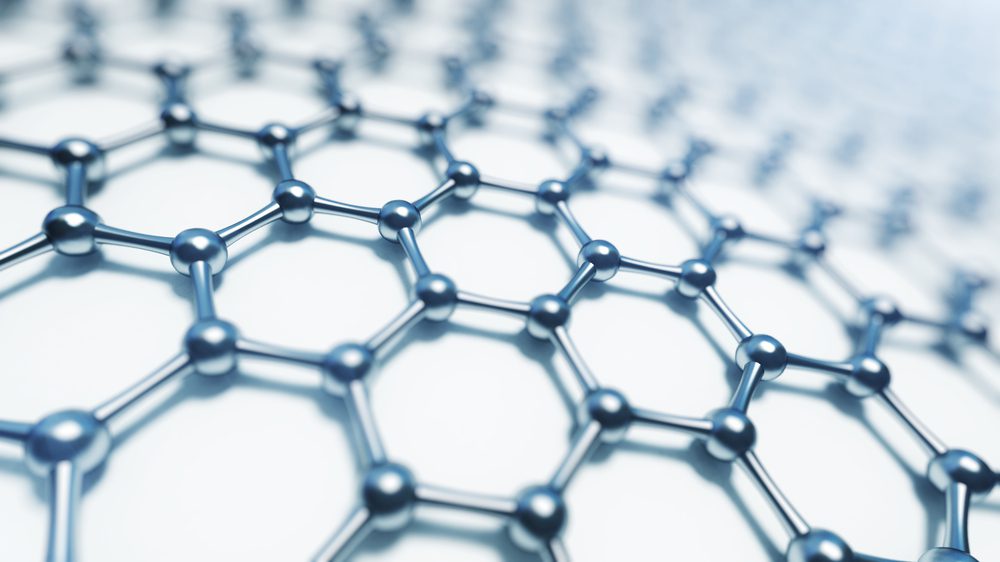

Next generation crosslinking nanoceramic technology, our coating forms a continuous, highly structured thin film on surfaces. ShieldSys™ MX120 generates a hard, non-stick coating on metallic, ceramic and plastic surfaces that offers supreme abrasion and chemical resistance and is ideal for continuous and high-throughput molding configurations.

- Next-Generation Crosslinking Technology

- Extremely Hard, Durable Thin-Film coating

- Exceptional Release and Anti-Stick Properties

- Ideal for continuous production, high throughput, and large mold configurations

Non Stick Release Coating | ShieldSys™ MX120

Next Generation Crosslinking Technology, Superior Durability and Non Stick Effect, Ideal for High Throughput Manufacturers

ShieldSys™ MX120 is a non stick release coating and sealer developed exclusively by Miller-Stephenson. MX120 is designed to provide a robust and efficient non stick coating for molders. Next generation crosslinking nanoceramic technology forms a continuous, highly structured thin film on surfaces. Once cured onto surfaces, the MX120 provides superior non stick properties, ease of cleaning, and excellent mold protection. Coated surfaces are substantially easier to clean and reduces buildup and fouling. The combined properties benefits molders with highly aggressive or tacky substrates. ShieldSys MX120 is ideally utilized for continuous mold release scenarios such as rollers, high throughput molds, large complex mold geometries and numerous other applications. Properly applied, our product develops a durable, thin film on surfaces typically between 1.0 – 5.0 µm. ShieldSys™ MX120 is ideally paired with one of our ReleaSys™ mold release agents to greatly extended coating life, reduce build up, and minimize reapplications.

Benefits of ShieldSys MX120 Non Stick Release Coating

- Next-Generation Crosslinking Technology

- Extremely Hard, Durable Thin-Film coating (<5um thickness)

- Exceptional Release and Anti-Stick Properties

- Ideal for continuous production, high throughput, and large mold configurations

- Provides unmatched lubricity and extremely low coefficient of friction

- Pairs seamlessly with any ReleaSys Coating System

- Can be applied to any metallic or ceramic surface

- Clean, Non-oily, Non-migrating

Application for ShieldSys MX120 Non Stick Release Coating

- Permanent Non stick coating for mold surfaces

- Corrosion and fouling protection

- Increase release performance or improve resin flow

- Reduce cleaning and downtime – particularly effective on Polyurethane and EVA molding operations

- High Throughput molding operations

- Injection Molding Unit

- Rollers and Embossing Tools

- Complex or Large Geometry Molds

ShieldSys™ MX120 Non Stick Release Coating offers exceptional performance and ease of application. Developed to eliminate the decision of manufactures between semi permanent mold release agents and expensive permanent solutions. ShieldSys MX120 is applied at room temperature and cured for 1 – 2 hours at temperatures 100 – 175°C. It can be applied with low pressure spray equipment or applied with cloth. Our formulation offer superior leveling and flow out, meaning that uneven application is automatically corrected for. The resulting cured coating will have a film thickness of < 5-10 microns. and offer superior anti corrosion and anti stick properties. This is typically seen most significantly in polyurethane molding where a water-based mold release system is utilized. To further improve overall performance and surface quality, Miller-Stephenson recommendations utilizing our ReleaSys 7400 or 7200W.

ShieldSys™ Permanent Release Coating – Cleaner Molds, More Consistent Release, Fewer Reapplication – a potent combination

ShieldSys™ MX120 can function as both a mold sealer and permanent release coating for a variety of configuration. Miller-Stephenson still typically recommends that a ReleaSys Mold Release Coating is used to help maintain, enhance, and extend the working life of the ShieldSys MX120. For recommendations on which coating would be best in your molding configuration please contact a Miller-Stephenson Technical Sales or Technical Support team member for a optimal recommendation. Unlike the ReleaSys™ MOLD SEALER which functions as solely a release enhancer, ShieldSys MX120 is dual functional and offers superior long term performance and durability.

Superior Release Coatings & Unmatched Customer Service

For any assistance with proper application, storage, or general technical assistance please see the links below or call our technical service line. Miller-Stephenson has a team of molding release experts ready to help you. Our staff hold the skills and experience needed to make sure your molding operation is cost effective, efficient, and safe. An excellent top coat for our ShieldSys MX120 Non stick release coating is ReleaSys 7200W, ReleaSys 8100 Polyurethane Release Agent or ReleaSys™ 8900.

50+ years of Industry Expertise at your service

Miller-Stephenson has had a long history in numerous molding industries, and our ReleaSys™ brand of products are respected around the world for quality and reliability. When you purchase Miller-Stephenson ReleaSys mold release agents you not only get industry leading products, you also gain access to our many years of direct production floor experience. We understand your production issues and can help you optimize your mold preparation, maintenance and release processes to improve your bottom line.

For help with application or troubleshooting concerns while using ReleaSys.

Click here for information, Which mold release agent is right for you

For further reading regarding our ReleaSys product line and Applications – our most helpful article for selecting the best product for your needs

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Bulk Sizes | Quart, 1 Gallon |