No products in the cart.

PTFE Release Agent and Dry Lubricant | MS-143HN

$171.35 – $471.14Price range: $171.35 through $471.14

MS-143HN is a versatile and robust release agent / dry lubricant, which utilizes a rapidly drying to enhance throughput and production efficiency.

SKU: N/A

Category: PTFE Bulk Liquid (MS-143)

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTPTFE Release Agent and Dry Lubricant | MS-143HN

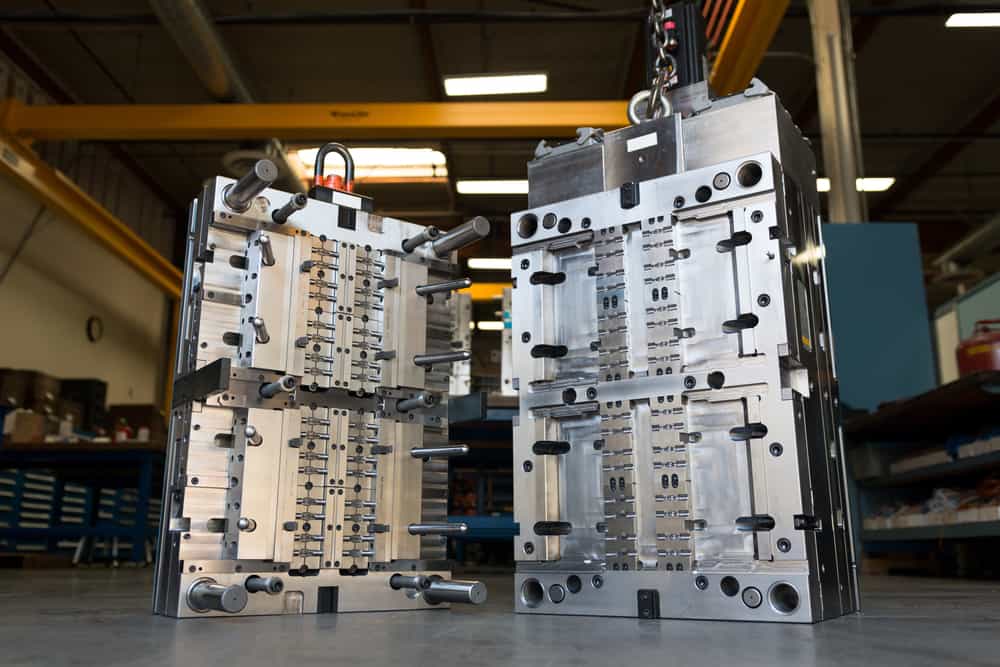

MS-143HN is a versatile and robust release agent / dry lubricant, which utilizes a rapidly drying to enhance throughput and production efficiency. The formulation contains a high lubricity, low molecular weight PTFE fluoropolymer designed to not interfere with posting finishing operations. It is used for metallic and nonmetallic molds. With its superior release action, it will yield up to three times the number of release cycle compared to the more economical Miller-Stephenson formulations. It is an excellent dry lubricant for all applications and surfaces. MS-143HN offers the following benefits:

- Efficient, consistent release of molded parts

- Outstanding lubricity and minimization of slip-stick

- Nonflammable, Non-ozone depleting

- Non-migrating; Non-staining

- Release Agent Applications

MS-143HN can be used to release the following materials with virtually no transfer of the release agent:

- Plastics

- Rubbers

- Resins

- Phenolics

- Acrylics

- Polycarbonates

- Urethanes

- Polystyrene

- Nylons

- Elastomers

Dry Lubricant Applications:

As a dry lubricant, MS-143HN is applicable to a variety of materials and will afford unmatched lubricity and wear resistance. These materials include:

- Metal

- Ceramics

- Glass

- Elastomers

- Rubber

- Polycarbonates

- Wood

- Elastomers

Physical Properties:

- Primary Polymer: Fluoropolymer

- Appearance: White Particle suspension

- Odor: Slight

- Specific Gravity: 1.24 g/mL @ 25°C

- Ozone depletion: 0.00

Recommended Application Procedure:

- Clean mold surface thoroughly. Mechanical cleaning such as bead media blasting or steel wool, followed by chemical cleaning, provides the best surface for application of MS-143HN. Removal of all previous mold release agent is critical.

- Mix product thoroughly prior and continuously during use. If spraying, use spray equipment which provides a fine mist and ensure the product is applied “wet”. Proper air pressure and spray distance is critical for correct application of this product. Apply to mold surface which is below 50°C.

- Allow solvent to dry completely before molding any parts. Failure to wait until all solvent is evaporated will result in drastically reduced product performance.

Reapplication:

- When release becomes hesitant, reapply one coat of MS-143HN in the same manner as described above.

Fused Coatings Procedure (Optional):

- After applying the release agent, heat the surface to 581ºF – 600ºF. Measure the surface temperature directly with a thermocouple.

- A change in coating appearance from an opaque white to a darker, translucent will occur. Maintain the temperature of the coated surface for 5 to 10 minutes.

- If a white residue is left on the metal surface, buff with a soft cloth. When the coating is properly fused, it is extremely durable.

Safety data sheet (SDS) is available upon request.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Bulk Sizes | Quart, 1 Gallon |

MS-143HN TDS

(pdf, 31KB)