Krytox™ GPL 207 Grease

Krytox™ GPL 207 grease has an Oil Viscosity of 450 cSt at 40°C and the estimated useful temperature range is -30°C to 288°C.

Krytox™ GPL 207 Grease | General-Purpose Lubricants

H-1 Certified For Incidental Food Contact, Chemically inert lubricants

Krytox GPL 207 grease is the product of choice in extreme temperature conditions. Most petroleum products begin to degrade above 99 °C (210 °F) and are too viscous at temperatures just below –18 °C (0 °F). Under the D-3336 test conditions of 177 °C (350 °F) and 10,000 rpm, the majority of competing hydrocarbon lubricants fail in less than 1,000 hr. But, the general-purpose line of Krytox lubricants has been shown to last over 5,000 hr without failure, even at an increased temperature of 200 °C (392 °F). This extreme condition performance is what distinguishes Krytox performance lubricants from other competing products.

Krytox GPL 207 grease is cost-effective across a wide range of applications. Due to their inert nature, Krytox lubricants provide a much longer usable life as compared to typical hydrocarbon oils and greases; and the longer usable life allows them to remain for considerable periods of time before needing to be replaced if they are replaced at all. That translates to savings over time, both by lowering the amount of lubricant purchased and any downtime incurred during re-lubrication.

Standard Krytox lubricants contain only carbon, oxygen, and fluorine; whereas, hydrocarbons contain hydrogen. The absence of hydrogen greatly increases the stability of the lubricants and renders them non-flammable with no flashpoint. They will not burn or support combustion, even in an environment of 100% liquid or gaseous oxygen. For applications that require GPL 201 and an extreme pressure additive, we recommend Krytox™ GPL 217, or if potent anti-corrosion is required Krytox™ GPL 227

Why Krytox GPL 207 Grease?

Krytox performance lubricants are not only resistant to oxygen but are also inert to virtually all chemicals used in a variety of industries. They are insoluble in most solvents but are soluble in highly fluorinated fluids and some supercritical fluids, such as CO2. At elevated temperatures and pressures, PFPE oils are highly resistant to attack by gaseous and liquid oxygen. As a result, Krytox oils and greases have become preferred lubricants in the oxygen manufacturing industry and in those industries that use oxygen.

Miller-Stephenson: Lubrication Experts, Superior Chemistry, Fast Delivery – a potent combination

At Miller-Stephenson, we understand the challenges engineers and scientists face with trying to select the best lubricant for current or new applications. With over 60 years of real-world experience, our highly trained team of technical experts and field engineers can assist you with identifying and selecting the optimal lubricant that best fits your operational parameter. Our large inventory of high-performance PFPE-base Krytox™ lubricants from Chemours, ensures we have the right lubricant for your needs, regardless of temperature, environment, safety, or performance of your system demands. For further information please review the articles below or contact a Miller-Stephenson representative.

Krytox™ is a trademark of The Chemours Company FC, LLC.

For more benefits and related articles:

To learn more about Krytox NSF H-1 Rated Food Grade Lubricants click here.

To learn more about Krytox Automotive Solutions click here.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

GPL Standard Grades | 200 | 201 | 202 | 203 (H-1 Certified) | 204 | 205 (H-1 Certified) | 206 (H-1 Certified) | 207 |

| GPL Extreme Pressure Grades | 210 | 211 | 212 | – | 214 | 215 | 216 | 217 |

| GPL Anti-Corrosion Grades | 220 | 221 | 222 | 223 (H-1 Certified) | 224 | 225 (H-1 Certified) | 226 (H-1 Certified) | 227 |

| Oil Viscosity Index | – | – | 29 | 92 | 111 | 124 | 134 | 145 |

Estimated Useful Range °F | -94-150 | -94-220 | -81-270 | -76-310 | -60-355 | -33-400 | -33-500 | -22-550 |

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

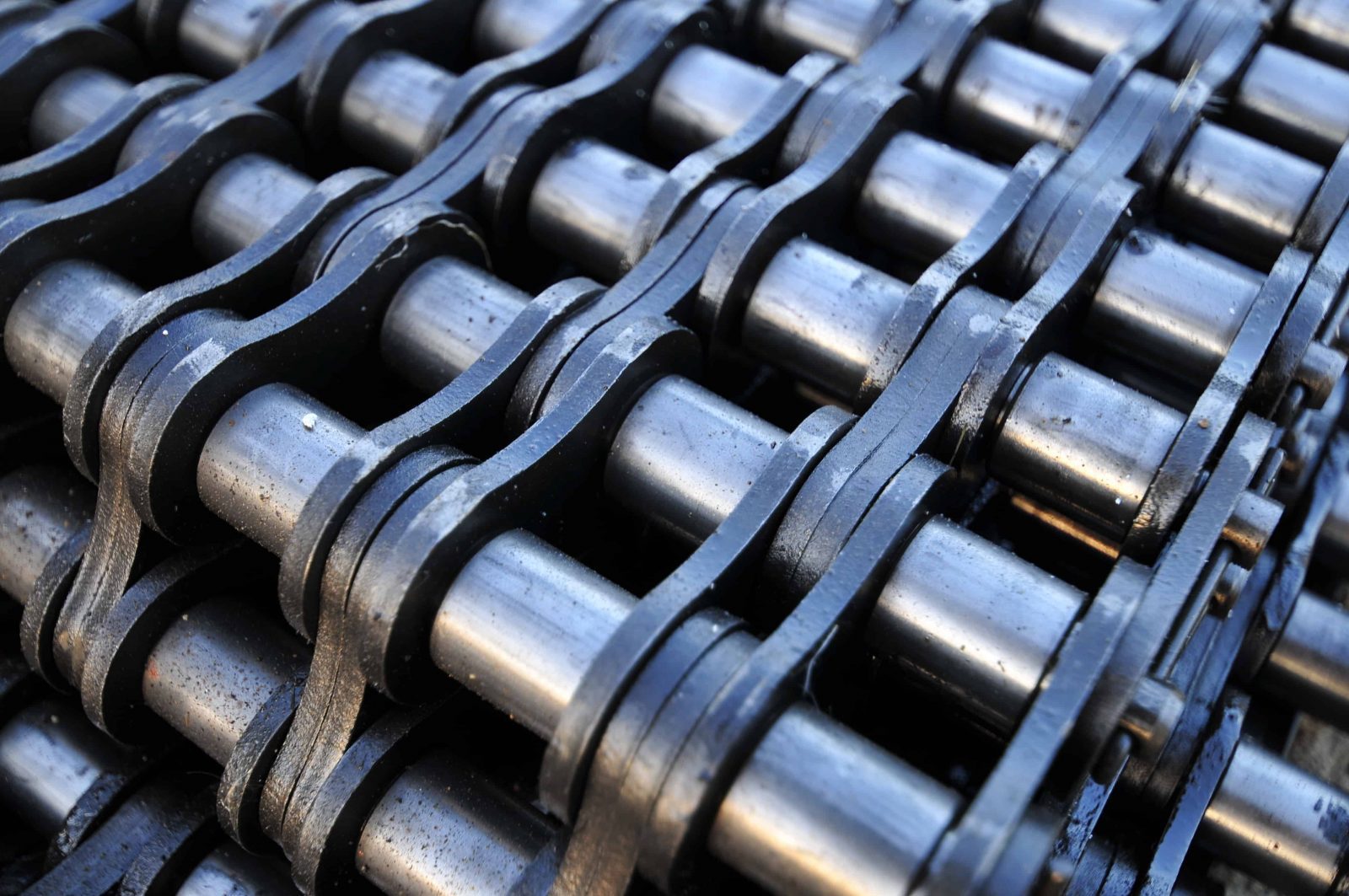

- Bearings

- O-Rings

- Valves

- Hinges

- Handles

- Moving Parts

- Seals

- Connectors

- Rollers

- Automotive Interiors

- Fittings

- Gearbox

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

| Syringe | Tube | Jar | Cartridge | Pail |

| 0.5 oz. | 2 oz. | 0.5 kg | 0.8 kg | 5 kg |

| 1 oz. | 4 oz. | 1 kg | 7 kg | |

| 2 oz. | 8 oz. | 20 kg |

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

- ASTM D2595

- ASTM D6184

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.