No products in the cart.

MS Epoxy Systems

Miller-Stephenson’s line of epoxy adhesives are made up of a polymer and a hardener, that when mixed together form an incredibly strong and durable bond that adheres to a wide range of surfaces. Epoxy adhesives are commonly used as industrial adhesives as well as adaptive structural adhesives. Their ability to create a strong, temperature and [...]

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTMS Epoxy Systems

Epoxsys 200 series are high-grade coating epoxies providing numerous advantages applicable to many different industries. Benefits include

- Odorless

- Primerless

- 100% solids and thixotropic

- Low curing heat

MS Epoxy Systems

The 700 series line of epoxy products from Miller-Stephenson feature highly modifiable properties that can adapt to meet any specification for your industrial filtration system. Benefits include:

- Maintain adhesion and bonding in high-temps

MS Epoxy Systems

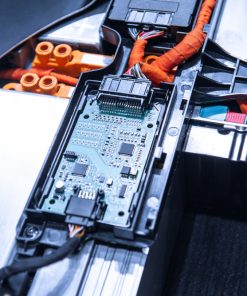

The Epoxsys™ 400 Series Potting Epoxies offers an array of finished epoxy potting solutions for multiple industrial applications. This family of potting epoxies offers a variety of products that can satisfy many physical properties needed for your application, such as

- Automotive sensor potting and encapsulations

- Electrical and Circuit board protection for utilities

- Deep-sea telecommunication cable

- PCB protection in commercial transportation

- Industrial Magnets

- Metal detectors

- Transformers

- Internal controls for lighting

Epoxy Adhesive Kit

MS-907 XPlus is a multi-purpose epoxy bond and repair adhesive. It’s specially formulated, non-sag property is ideal for bonding most materials, such as metal, glass, ceramics, plastics, wood, rubber, and concrete. MS-907 XPlus is a two-part, equal volume, room temperature curing system. Benefits Include:

- Fast set-up time

- Room Temperature Curing System

- Perfect for in-plant and field use

- Useful Temperature Range (40°F/4°C to 110°F/43°C)

Epoxy Stripping Agent

Price range: $145.00 through $195.52

ShieldSys™ ES1 Epoxy Stripper is a powerful, industrial strength cleaner and stripper, formulated for removal of all epoxies, urethanes, enamels and paints. Effectively removes most coatings in less than 1 hour. 100% Methylene Chloride and Chlorinated solvent free.

- Industrial Strength Stripping of Epoxies, Enamels, Urethanes, and other Coatings

- Methylene Chloride and Chlorinated Solvent Free

- Soften and Removes the most stubborn coatings at room temperature, no heating required

- Low Odor and Volatility

- Direct replacement for MS-111

Poly-functional Glycidyl Ethers

HELOXY™ Modifier 107 is the diglycidyl ether of cyclohexane dimethanol. While it is primarily used as a reactive diluent or viscosity reducing modifier for epoxy resin formulations, it also can effectively serve as a reactive intermediate for further synthesis of various cycloaliphatic based resins. Benefits include:

- Reduces viscosity of epoxy formulations while maintaining most cured state properties

- Provides excellent cured state resistance to creep or deformation under high stress

- Effective means of incorporating a cycloaliphatic structure into the polymer chain

Mono-functional Aliphatic Glycidyl Ethers

HELOXY™ 116 Modifier is a commercial grade of 2-ethylhexyl glycidyl ether. A low viscosity, almost colorless monoepoxide, its primary use is the viscosity reducing modification of epoxy resin formulations. Benefits include:

- Efficient viscosity reduction of conventional epoxy resins

- Excellent substrate and filler wetting characteristics

- Low volatility relative to other members of monoepoxide class

Poly-functional Glycidyl Ethers

HELOXY™ Modifier 48 is a low viscosity aliphatic triglycidyl ether useful in the viscosity, reactivity, and performance modification of epoxy resin systems. Applications can be fast setting adhesives, Low temperature curing floor surfacing and concrete patching compounds, hard abrasion resistant clear castings and decoupage systems. Benefits include:

- Reduces viscosity but retains reactivity of conventional and polyfunctional epoxy resins

- Imparts hardness and toughness to epoxy systems cured with low functionality curing agents

- Improves solubility/compatibility characteristics of highly aromatic epoxy resins without reducing functionality

Mono-functional Aliphatic Glycidyl Ethers

HELOXY™ Modifier 61 is a commercial grade butyl glycidyl ether. A low viscosity, virtually colorless monoepoxide, it is widely used in the viscosity reducing modification of epoxy resin formulations. The relatively low molecular weight of HELOXY 61 makes it the most efficient common monoepoxide in reducing the viscosity of basic epoxy resin formulations. Benefits include:

- Most efficient epoxy resin viscosity reduction of all common epoxy functional modifiers

- Outstanding substrate and filler wetting characteristics

- Excellent retention of physical strength and thermal properties of base formulations

Mono-functional Aromatic Glycidyl Ethers

HELOXY™ 62 is a commercial grade of o-cresyl glycidyl ether. A low viscosity aromatic monoepoxide, its primary use is the viscosity reduction of conventional epoxy resin systems. Benefits include:

- Reduces viscosity of higher molecular weight aromatic epoxy resins

- Excellent retention of mechanical and chemical resistance cured state properties relative to othermonoepoxides

- Low volatility

- Improves substrate and filler wetting of conventional formulations

Poly-functional Glycidyl Ethers

HELOXY™ Modifier 68 is a diglycidyl ether of neopentyl glycol and is primarily used as a reactive diluent or viscosity reducing modifier for all classes of epoxy resins. Benefits include:

- Reduces viscosity while maintaining most cured state properties

- Improves wetting characteristics

- Facilitates air release

HELOXY™ Flexibilizers

HELOXY™ Modifier 71 is an undiluted amber colored, low-viscosity liquid, aliphatic epoxy ester resin that imparts increased flexibility and resistance to thermal shock when blended with conventional liquid bisphenol A based epoxy resins. Benefits include:

- A low-viscosity flexibilizer that serves as a viscosity depressing agent

- A product that improves impact strength and toughness to a conventional liquid bisphenol A epoxy resin

MS Epoxy Systems

EpoxSys™ 1200 Marine Epoxy is a high-grade resin system ideal for new and restoration marine applications for boats and aquatic vessels. Benefits inlcude:

- Excellent thin film properties

- Easy to mix by volume

- Strong fairing and filleting adhesive

- Easy to apply with various applicators

Epoxy Stripping Agent

Our MS-111 Epoxy Stripping Agent has been discontinued. Our new drop in replacement product is:ShieldSys™ ES-1 Epoxy StripperFor technical inquiries, please call, chat, or use the inquiry buttons below to email us.Phone: 1-800-992-2424

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTMS Epoxy Systems

Optimizing Renewable Energy Products with New Epoxy Potting Systems Epoxy Resins have numerous applications in the field of energy and power. Their strengths may be utilized in the construction of wind turbines, batteries, solar panels, and other electrical components. Characteristics of Miller-Stephensen’s Epoxys as they apply to the renewable energy industry include: Maximum Adhesion and [...]

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTEPI-REZ™ Water-borne Resin

EPI-REZ™ Resin 3522-W-60 is a non ionic, aqueous dispersion of a solid bisphenol A epoxy resin similar to EPON™ Resin 1002F, with an epoxide equivalent weight of 550 to 650 and a Durran’s melting point of 75 to 85 °C. EPI-REZ 3522-W-60 is supplied at a moderate viscosity and is mechanically stable. No organic solvents are present. EPI-REZ 3522-W-60 offers a solvent-free approach to the formulation of film adhesives, fiberglass reinforced plastics, chemical resistant pipe, and electrical dip coatings and varnishes. In addition, EPI-REZ 3522-W-60 can be used in the formulation of coatings where conventional solvent based epoxy resins are normally used.

- Non-ionic, aqueous dispersion

- No organic solvents

- Offers solvent-free formulations

EPI-REZ™ Water-borne Resin

EPI-REZ™ 5003-W-55 is a nonionic aqueous dispersion of a polyfunctional aromatic epoxy resin with an average functionality of three. It is intended for high performance applications such as industrial fabric finishes and adhesives which require maximum chemical and solvent resistance and/or elevated temperature service.

- Maximum Chemical and Solvent Resistance

- Nonionic Aqueous Dispersion

EPI-REZ™ Water-borne Resin

EPI-REZ™ 5522-WY-55 is a polyfunctional epoxy resin dispersion is intended for use in ambient cure, two-component, water reducible epoxy coatings formulated for applications requiring a high degree of chemical and corrosion protection. Although EPI-REZ 5522-WY-55 exhibits good compatibility with several amine functional water reducible converters, it is suggested for use with water reducible EPIKURE™ 8290-Y-60 Curing Agent. Clear paints, enamels and primers for metal, concrete or masonary can be formulated with EPI-REZ™ 5522-WY-55. Benefits include:

- Rapid room temperature cure; Low VOC

- Good paint stability; Performance versatility

- Long-term water and humidity resistance

- Corrosion resistance over a variety of substrates

- Adhesion to damp concrete

EPI-REZ™ Water-borne Resin

EPI-REZ Resin WD 510 is a liquid, bisphenol A type epoxy resin specifically designed for water dilution. In combination with epoxy curing agents and dilution with water it forms resin in water emulsions. It is useful as a modifier for Portland Cement, concrete, mortars, stuccos, and grouts. As a binder it is useful for trowel applied floor toppings, bond coats, base coats, membrane coatings and sealers. EPI-REZ WD 510 forms uniform dispersion in water in combination with Aliphatic amine curing agents, including adducts, amidoamines, polyamides, and accelerated amines. Benefits Include:

- Specifically designed for water dilution emulsions

- Bisphenol A type epoxy resin

- Can be used as a modifier and binder