No products in the cart.

Opteon SF10 Chemours Specialty Cleaning Fluid

Opteon™ SF10, formerly Opteon™ Suprion carrier fluid is a clear, colorless, nonflammable, thermally stable, fluorinated fluid developed in response to worldwide market demand for a low environmental impact solvent for cleaning, as a carrier fluid, and many other applications.

- Alternative to Vertrel XF

- Removes particulate & ionic soil

- Ideal for: vapor degreasing, precision cleaning, co-solvent rinsing and drying agent

- Low GWP, zero ODP, 100% non-flammable

This product is already in your quote request list.

Category: Opteon™ Solvents

Tags: Degreaser, Opteon, sf10, Suprion, Vapor, vapor degreasing

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTOpteon SF10 Chemours High Performance Specialty Fluid

Precision Cleaning and Carrier Fluid, Ultra-low GWP, Non-Flammable, Excellent Alternative to Vertrel XF

Opteon SF10 carrier fluid is a clear, colorless, nonflammable, thermally stable, fluorinated fluid developed in response to worldwide market demand for a low environmental impact solvent for cleaning, as a carrier fluid, and many other applications. The fluid has a boiling point of 110 °C (230 °F), zero ozone depletion potential (ODP), and a very low global warming potential (GWP) of 2.5 (100-yr ITH). Opteon™ SF10 carrier fluid is appropriate to replace PFCs, PFPEs, HFEs, HFCs, and HCFCs in carrier fluid applications.

Typical Applications of Opteon SF10

- Cleaning agent

- Carrier fluid in coatings and adhesives

- Aerosol solvent

Safety, Toxicity, and Environmental

Opteon SF10 carrier fluid is a nonflammable fluid and does not become flammable during boiling or evaporation with thermal stability up to more than 175 °C (347 °F). The material has safe toxicity profile in mammalian studies, and it’s not a skin or eye irritant in laboratory tests. In environmental studies, Opteon™ SF10 carrier fluid exhibited low concern for aquatic life. The occupational exposure limits for Opteon™ SF10 carrier fluid is 500 ppm. Results of extensive toxicity testing studies are available in the Safety Data Sheet.

Environmental Properties

| Property | Opteon™ SF10 Carrier Fluid |

| Ozone Depletion Potential (ODP) | 0 |

| Global Warming Potential (GWP) 100-yr ITH | 2.5 |

| Atmospheric Lifetime | <10 days |

| Volatile Organic Compound | Not yet determined |

Physical Properties of Opteon SF10

Recommended operating range in heat transfer applications: -80 to 105 °C (-112 to 221 °F).

| Property (at 25 °C [77 °F]) | Units | Opteon™SF10 Carrier Fluid |

| Molecular Weight | – | 362 |

| Boiling Point | °C (°F) | 110 (230) |

| Freezing Point | °C (°F) | < -90 (<-130) |

| Critical Temperature | °C (°F) | 240 (464) |

| KB Value | 6 | |

| Liquid Density | kg/m^3 (lb/gal) | 1580 (13.1) |

| Liquid Viscosity | cSt | 0.71 |

| Liquid Specific Heat | kJ/kg-K | 1 |

| Liquid Thermal Conductivity | W/m-K | 0.065 |

| Surface Tension | dyn/cm | 18 |

| Vapor Pressure | kPa | 2.9 |

| Heat of Vaporization | kJ/kg | 115 |

| Solubility in Water | ppm (w/w) | <1 |

| Water Solubility | ppm (w/w) | 80 |

| Flash Point, CC, ASTM D56 | – | None |

| Flash Point, OC, ASTM D1310 | – | None |

| Vapor Flammability, ASTM E681 | – | None |

Vapor Pressure

Please refer to the following equation to predict vapor pressure as a function of temperature.

Vapor Pressure (kPa) = exp(14.65 – 3280/[T + 216.4]) T in °C

Storage and Handling for Opteon SF10

Opteon SF10 carrier fluid is thermally stable, does not oxidize or degrade during storage, and has no shelf life. Store product in a clean dry area, protect from freezing temperatures, and do not allow stored container to exceed 52 °C ( 125.6 °F). Package sizes for Opteon™ SF10 carrier fluid are available in 6 and 15 kg net weight in high density polyethylene containers and in 300 kg stainless steel drums. When pumping or transferring Opteon™ SF10 carrier fluid from a drum, a braided stainless steel hose is recommended. If a flexible hose is desired, a static charge dissipation hose is recommended, i.e., one constructed with carbon black-filled nylon inner core conductive material.

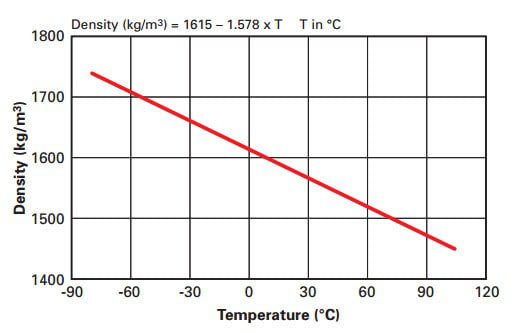

Liquid Density

The temperature dependence of liquid density for Opteon™ SF10 carrier fluid is shown below

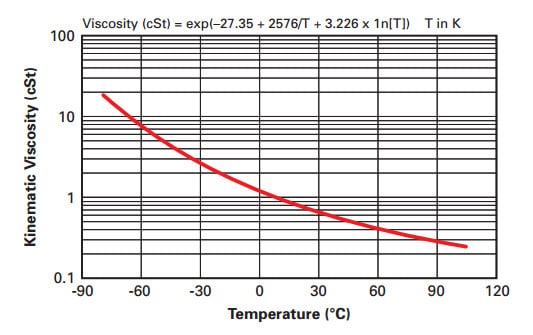

Liquid Viscosity

The temperature dependence of liquid viscosity for Opteon™ SF10 carrier fluid is shown below.

Critical Heat Flux

The critical heat flux of Opteon SF10 carrier fluid was estimated at 16 W/cm^2, but the actual value in use will depend on heater geometry and operating conditions. It is recommended that users consult with their local Opteon™ specialty fluids representative for applications requiring a heat flux greater than 12 W/cm^2.

Miller-Stephenson – 60 years of Technical Expertise…..at your service!

Miller-Stephenson is helping companies convert from nPB-based solvents to effective, safe and compliant alternatives. The goal of our support is that the replacement fluid will deliver cleaning results as good as or better than nPB at a similar cost-per-part-cleaned. Our support is designed to reduce the research and confusion of selecting a new chemistry, and ensuring a smooth and seamless transition. Miller-Stephenson can offer this commitment because we have a team of cleaning engineers, chemists and technical staff with dedicated to helping your transition, we offer on-site and off-site technical assistance. When the conversion begins, we launch our on-site technical support and a comprehensive product Stewardship Program. This program is designed to help each company lower cleaning costs, improve worker safety and protect the environment. The program educates workers about the cleaning products and processes, plus audits company procedures to ensure everyone works safely and profitably.

To learn more about the Opteon™ series click here.

Next-Generation Cleaning Fluids and Precision Solvents – Alternatives to nPb

Opteon™ is a trademark of The Chemours Company FC, LLC

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

| Property @ 25°C (77°F) | |

| Molecular Weight | 362 g/mol |

| Boiling Point | 110°C (230°F) |

| Freezing Point | <-90°C (<-130°F) |

| Critical Temperature | 240°C (464°F) |

| KB Value | 6 |

| Liquid Density | 1580 kg/m3 (13.1 lb/gal) |

| Liquid Viscosity | 0.71 cSt |

| Liquid Specific Heat | 1.0 kJ/kg-K |

| Liquid Thermal Conductivity | 0.065 W/m-K |

| Surface Tension | 18 Dyn/cm |

| Vapor Pressure | 2.9 KPa |

| Heat of Vaporization | 115 kJ/kg |

| Solubility in Water | <1 ppm |

| Water Solubility | 80 ppm |

| Flash Point, CC ASTM D56 | None |

| Flash Point, OC, ASTM D1310 | None |

| Vapor Flammability, ASTM E661 | None |

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

Opteon Suprion PDF

(pdf, 119KB)

Technical Data Sheet

- Cleaning agent

- Coating agent (carrier fluid) for fluorinated materials

- Aerosol Solvent

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

| Glass | Pail |

| Quart. | 5 Gallons |

| 1 Gallon | 55 Gallons |

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

- ASTM D56

- ASTM D1310

- ASTM E661

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.