No products in the cart.

Epoxy Potting | Epoxsys™ 400 Series

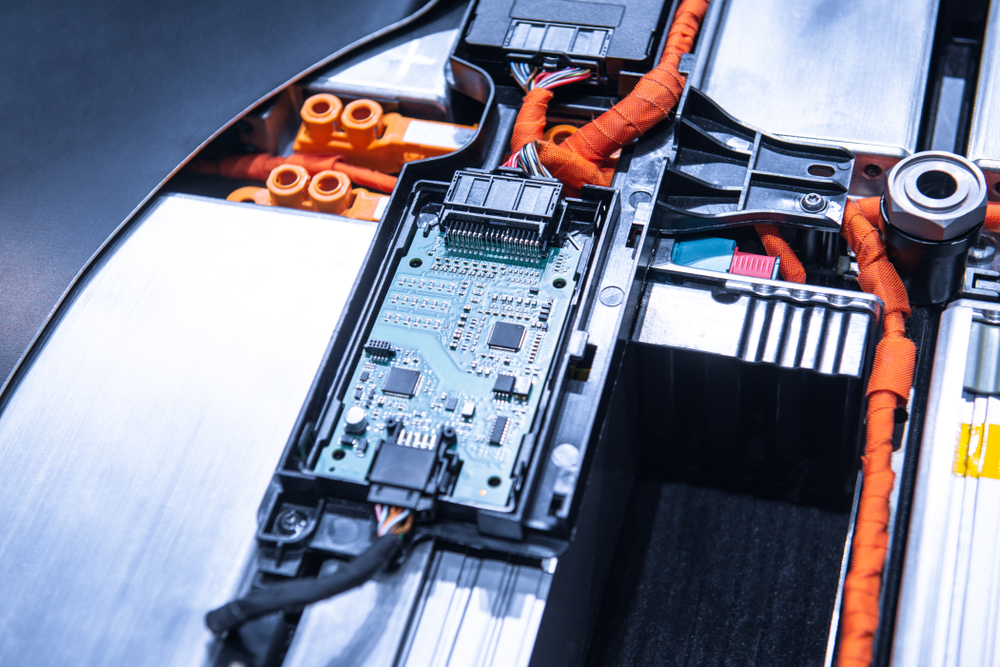

The Epoxsys™ 400 Series Potting Epoxies offers an array of finished epoxy potting solutions for multiple industrial applications. This family of potting epoxies offers a variety of products that can satisfy many physical properties needed for your application, such as

- Automotive sensor potting and encapsulations

- Electrical and Circuit board protection for utilities

- Deep-sea telecommunication cable

- PCB protection in commercial transportation

- Industrial Magnets

- Metal detectors

- Transformers

- Internal controls for lighting

This product is already in your quote request list.

Category: MS Epoxy Systems

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTMiller-Stephensons EpoxSys™ 400 Series for Epoxy Potting Applications

The EpoxSys™ 400 series is a new finished solution, that will help improve the overall cost-efficiency and production in your epoxy potting applications. Our experienced design and manufacturing team can also customize each product to meet the specific needs of your application, delivering a process improvement savings of 15–50%. Our custom-formulated epoxy potting solutions will help protect your electronic devices and machinery, drastically improve longevity, and bolster user safety. So if you’re looking for top-quality epoxy potting products that exceed your expectations, most likely Miller-Stephenson has the solution.

What are the top Epoxy Potting uses?

Fundamentally, epoxy potting has an advantage when it comes to moisture resistance. Most outdoor applications can benefit from epoxy potting as an encapsulate for this reason. Additionally, epoxy potting is on the high-end of the adhesion scale and is also spectacularly resistant to high temperatures and various chemicals.

Top uses of epoxy potting compounds include:

- Automotive sensor potting and encapsulations

- Circuit board protection for utilities

- PCB protection in commercial transportation

- LED driver protection

- Deep-sea telecommunication cable protection

- Industrial Magnets

What is Epoxy Potting?

Epoxy potting compounds are developed within higher mechanical strength ranges while still adhering to expectations of maintaining their integrity for temperatures under 180 degrees. As a result, Epoxy Potting tends to be on the less-flexible side of the epoxy compounds. These encapsulants hold their own in rough environmental conditions and are looked to when a robust adhesive is necessary to encapsulate and protect components.

What to consider when choosing an Epoxy Potting Compound?

Viscosity

Viscosity is a measurement of how well something permeates other substances based on its magnitude of internal friction, reflected by the units: centipoise (cps) and millipascal second (mPa-s). Epoxies (particularly epoxy potting) are fluids that change their viscosity based on shearing speed. Epoxies fall into the following three categories:

- Low-viscosity: 0.08 – 0.25 cps

- Medium-viscosity: 0.26 -0.75 cps

- High-viscosity: >0.76 cps

Medium or High viscosity epoxy pottings are useful for filling cracks, holes, or gaps in products. If a shorter curing time is necessary, low-viscosity epoxy pottings are the best option. Both low and medium-viscosity epoxy pottings are a good solution if your application involves fluid layers. When prototyping, pair your epoxy pottings with an accelerator to speed up the process. Low viscosities are also great for potting if you need something that’s easier to remove than medium or high-viscosity materials (ex. An electric motor with delicate insides that may need access). Low-viscosity epoxy pottings are better if you’re working with delicate components that are prone to breaking.

Mix Ratio

Mix ratios are a crucial element of the building process. The ratio between resin and hardener can affect how well they cure or remain flexible, which in turn helps with performance- so it’s important to have a mix ratio plan in place. We can help you find the best mix ratio for your application. The chemical structure of two compounds might differ to the point that their interaction is governed by a different chemical formula. It’s possible to convey this in a variety of ways:

- Weight ratios (e.g., 10 grams of resin and 10 grams of hardener)

- Volume ratios (e.g., 1 cup of resin and 1 cup of hardener)

- Non-fractional ratios (e.g., 2 parts resin to 1 part hardener)

- Fractional ratios (e.g., 2.3 part resin to 1 part hardener)

Color

To create a color system that is tailored specifically to an application, resin systems can be filled with pigments and additives. Some fillers have natural colors while others take on different tones depending upon what they’re mixed up in – but all will maintain the same clarity as their un-filled counterparts.

Cure Requirements

Different applications call for varying cure requirements. Epoxy pottings come in a range of hardnesses, so it’s important to make sure that the material you select can cure properly in its respective environment. For example, an epoxy that is designed for outdoor use might not be suitable for a project that requires an indoor cure. All of the materials from our website are based on General Purpose Resin, and they can be used in an array of applications. That being said, some products may need to be modified slightly by adding different hardeners or fillers – so if you have any questions about which one will work best for your application feel free to ask us.

The curing process occurs in stages. The first stage or initial period of time refers to mixing where an epoxy has hardened but is still pliable enough to adjust its composition. Next, we enter into our gel-time where all those amazing changes happen which will lead us towards full cure status – when chemical reactions occur at their optimal levels (which means no interruptions), giving your product the final shape.

Cured Physical Properties

Depending on the application, different physical properties are required. If a product is meant to be flexible and expand with heat, you might require low hardness and pliability at room temperature. In contrast, if you’re producing electrical connectors that need high mechanical strength but not so much flexibility (in addition to corrosion resistance) then you might want your epoxy to have a high hardness at room temperature. This is within our capabilities if necessary.

Take into account the following features of a system before selecting an potting epoxy:

- Adhesion

- Durability

- Thermal conductivity

- Flame retardance

- Flexibility

- Mechanical strength

- Electrical conductivity

- Environmental factors

Epoxy Potting Removal

Researching how to remove epoxy potting when the time comes? Miller-Stephenson also offers a line of stripping compounds to counter the strength of our Epoxy Potting products for removal. Epoxy Potting residue can be manageably stripped away after any of our stripping compounds dissolve the no longer needed seal. For effective Epoxy Stripping agents, we recommend MS-111.

Miller-Stephenson is here to help with your epoxy application needs.

The EpoxSys 400 Series for Potting Epoxy applications, is one of the many epoxy resin systems offered through the EpoxSys line of epoxy products. Epoxsys products offer a variety of solutions to match a wide range of production and processing needs, so you’ll be sure to find the results you need for a successful result. Contact our sales team today, who will work with you to recommend the right product solution for your application needs. Available through phone, chat, or email your inquiry with the form below.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.