No products in the cart.

Electrical & Electronic Epoxies | Epoxsys™ 500 Series

Electrically conductive epoxies provide minimal squeeze-out during bonding, superior bond strength, and uniform bond line thickness. Some of the properties of these formulas include:

- Extraordinary toughness

- Moderate curing temperatures

- Good storage ability

This product is already in your quote request list.

Category: MS Epoxy Systems

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTMiller-Stephensons EpoxSys™ 500 Series for Electronic Epoxy Applications

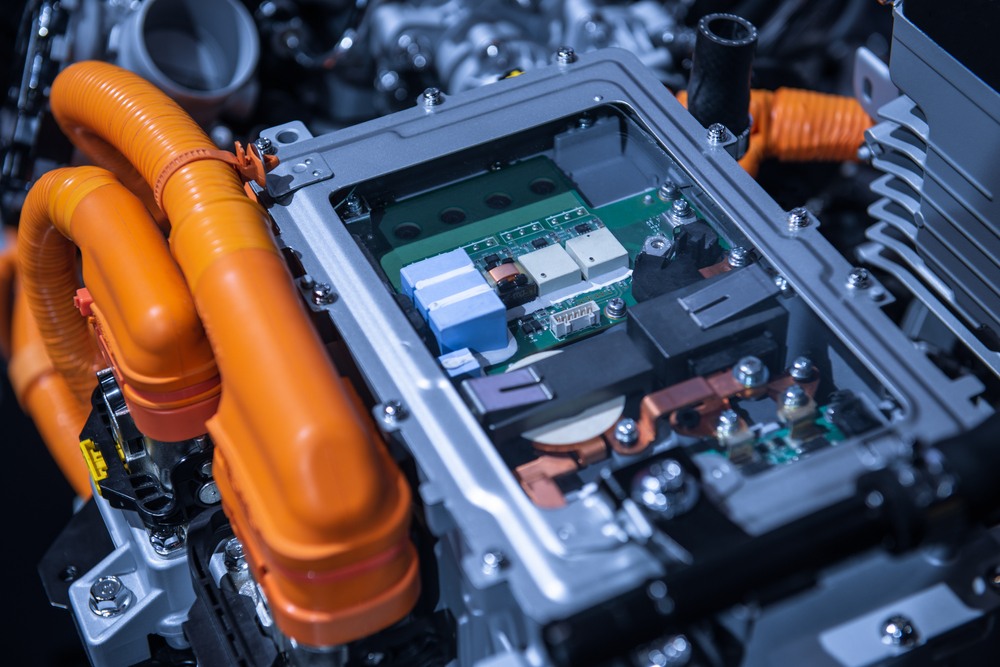

Ideal for use in thermal, interconnecting, and structural bonding applications, Miller-Stephenson provides epoxies for improved performance and reliability in electronic systems. Each of the conductive pastes, adhesives, and epoxies delivers the best performance and enhances any assembly or application by ensuring superior conductivity, efficient thermal dissipation, and strong bonds.

Electronic Epoxy Applications and Use

Depending on the application, different physical properties are taken into consideration. If a product is meant to be flexible and expand with heat, you might require low hardness and pliability at room temperature. In contrast, if you’re producing electrical connectors that need high mechanical strength but less flexibility (in addition to corrosion resistance) then an epoxy with high hardness at room temperature should be used. Our high-quality line of Epoxy products can be designed to match any application.

Application Methods for Electrical Epoxies

With both one and two-part options available, our electrically conductive epoxies offer a wide scope for electronic assembly and flexibility for the production line. Different methods of application of these products include

- Jetting

- Screen printing

- Dispensing

Features of the EpoxSys™ 500 Electronic Epoxy

Take into account the following features of a system before selecting an adhesive:

- Adhesion

- Durability

- Thermal conductivity

- Flame retardancy

- Flexibility

- Mechanical strength

- Electrical conductivity

Electrically Conductive Epoxies

This line of epoxy products from Miller-Stephenson provides minimal squeeze-out during bonding, superior bond strength, and uniform bond line thickness. Some of the properties of these formulas include:

- Extraordinary toughness

- Moderate curing temperatures

- Good storage ability

Available with custom cut performs for a wide range of applications, the films may also be cut into different shapes and sizes and do not require freezing.

The versatility of Epoxsys 500 Series Electronic Epoxy Products

Electrically conductive epoxy products may be more suitable for bonding and adhesion for a number of reasons. Used as an alternative to soldering when components are temperature sensitive, electronically conductive epoxies provide a low-temperature curing process that allows for use with sensitive components, the flexibility of processing, and lower energy consumption.

Ideal for use in thermal, interconnecting, and structural bonding applications, Miller-Stephenson provides epoxies for improved performance and reliability in electronic systems. Each of the conductive pastes, adhesives, and epoxies delivers the best performance and enhances any assembly or application by ensuring superior conductivity, efficient thermal dissipation, and strong bonds.

For applications that require both thermal dissipation and high electrical performance, the Epoxsys 500 series conductive adhesives provide superior dependability and integration for a range of industrial and manufacturing processes. Each formula can be designed to match your required application and environment.

Combining these one or two-part formulas with silver makes them an effective substitute for any application that would usually require soldering.

Some of the common applications of these products include:

- Radar

- LiDar

- Cameras

- ADAS Data Modules

- ECUs

The flexibility of our products provides increased processability and applications for these and many other possible industrial or manufacturing applications.

Miller-Stephenson is here to help with your epoxy application needs.

The EpoxSys 500 Series for Electrical and Electronic Epoxy applications, is one of the many epoxy resin systems offered through the EpoxSys line of epoxy products. Epoxsys products offer a variety of solutions to match a wide range of production and processing needs, so you’ll be sure to find the results you need for a successful result. Contact our sales team today, who will work with you to recommend the right product solution for your application needs. Available through phone, chat, or email your inquiry with the form below.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.