No products in the cart.

Connector Lubricant | TriboSys™ MS-381HC/383H

Formed by combining the superior lubricating qualities of Polyphenyl Ether with the cleaning power of a hydrofluoroether azeotrope. Miller-Stephenson has created a nonflammable, Non-ozone-depleting connector lubricant, a formulation that provides the most advanced total treatment for connectors with no interference in electrical continuity.

- Cleans lubricates and protects multi-pin connectors

- Is non-migrating & contains no silicones

- Available with a UV (ultraviolet) indicator

- NSN-6850-01-538-3496 (MS-383H)

- RoHS2 and RoHS3 Compliant

- Extends connector life by preventing corrosion and fretting

This product is already in your quote request list.

Category: Connector Lubricants

Tags: Connector, fretting prevention, Lubricant, MS-381, MS-383

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTConnector Lubricants | TriboSys™ MS-381HC/383H

Six (6) Ring Polyphenyl Ether Lubricant, Prevents Fretting On Sensitive Connectors

TriboSys™ MS-381HC/383H connector lubricants were formed by combining the superior lubricating qualities of Polyphenyl Ether with the cleaning power of a hydrofluoroether azeotrope. Miller-Stephenson has created a nonflammable, Non-ozone-depleting connector lubricant, a formulation that provides the most advanced total treatment for connectors with no interference in electrical continuity.

Advantages

- Cleans lubricates and protects multi-pin connectors

- Reduces insertion forces

- Greatly increases mating cycles (especially important

where high pin counts are involved) - Extends connector life by preventing corrosion and

galling - Removes contaminants and oxides.

- Is non-migrating-contains no silicones

- Available with a UV (ultraviolet) indicator

- NSN-6850-01-538-3496 (MS-383H)

- RoHS2 and RoHS3 Compliant

VOC content of MS-381HC………………………………….522 gms/l

VOC content of MS-383H…………………………………….699 gms/l

The active ingredient of Connector Lubricant is a six (6) ring polyphenyl ether lubricant. This lubricant will help protect metal connector surfaces from excessive wear, when subjected to hundreds of mating cycles, thereby increasing the life of the connectors. It will also reduce insertion forces and provide corrosion protection in harsh environments. Polyphenyl ethers (PPE) are very viscous fluids and only a very thin film is required. Connector Lubricant MS-381HC/383H is a 2% PPE concentration, which is at the proper concentration for connectors operating at room temperatures where there is little or no vibration. Higher concentrations are available in Bulk formulations.

Connector lubricants : Available Sizes

TriboSys™ MS-381HC (16 oz Aerosol)

TriboSys™ MS-381HCM (8 oz Aerosol)

TriboSys™ MS-383H (1 oz, 4 oz, 8 oz, Qt, Gal, 5G, 55G)

Maximum Operating Temperatures

Estimated 20 year film life 230°F/110°C

Estimated 5 year film life 257°F/125°C

Note: Higher temperatures result in shorter film life.

Physical Properties: 6-ring Polyphenyl Ether

Surface Tension 54.2 dynes/cm

Evaporation Loss (ASTMD-972) 6.5 hrs.

400°F/204°C @ 760mm 0.04%

500°F/260°C @ 760mm 0.50%

500°F/260°C @ 140mm 1.10%

Oxidation – Corrosion wt.change of metals, mg ASTM D 4636 (FTM 791-5307/5308) 600°F, 48h

Aluminum 0.04

Titanium 0.02

Steel 0.02

Copper 0.14

Silver 0.03

Thermal Stability 836°F/447°C

Low-Temperature Performance: Performs consistently over a wide range of low temperatures to – 20°C.

Electrical Properties: 6-ring Polyphenyl Ether

Dielectric Constant 60cy 1kc 10kc 100kc (@ 77°F/25°C)

4.54 4.54 4.55 4.53

Resistivity @ 77°F/25°C @ 500VDC 1.56 x 1014ohm-cm

Dielectric Strength- 43 Kv

Krytox™ is a trademark of The Chemours Company FC, LLC.

For more benefits and related articles:

To learn more about Krytox NSF H-1 Rated Food Grade Lubricants click here.

To learn more about Krytox Automotive Solutions click here.

To learn more about Krytox Automotive Noise, Harshness and Vibration solutions click here.

For the Krytox Frequently asked questions (FAQ) click here.

For a general Krytox application overview, click here.

With help regarding which Krytox grease is right for you, click here.

For Technical Assistance please click here.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

- Cleans, lubricates and protects multi-pin connectors

- Reduces insertion forces

- Greatly increases mating cycles (especially important where high pin counts are involved)

- Extends connector life by preventing corrosion and galling

- Removes contaminates and oxides.

- Is non-migrating-contains no silicones.

- Non ozone depleting

- Available with an UV (ultraviolet) indicator

- No interference in electrical continuity

- Nonflammable

- NSN 6850-01-519-8521 (MS-381H)

- NSN-6850-01-538-3496 (MS-383H)

- RoHS Compliant

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

MS-381HC

(pdf, 18KB)

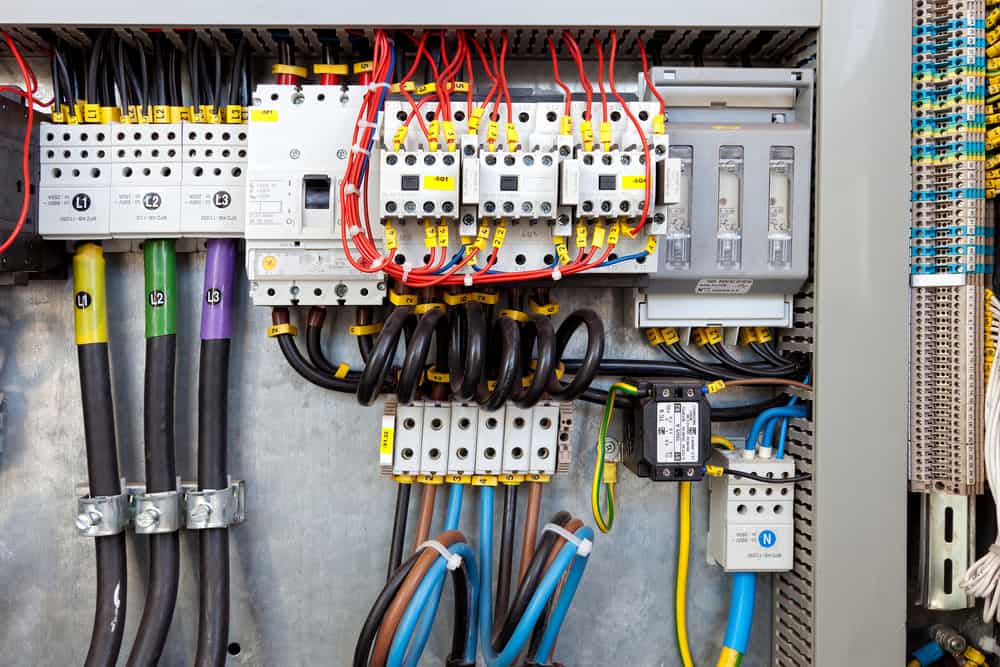

- Connectors

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

MS-381HC (16 oz Aerosol)

MS-381HCM (8 oz Aerosol)

MS-383H (1 oz, 4 oz, 8 oz, Qt, Gal, 5G, 55G)

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.