No products in the cart.

High Performance Silicone Conformal Coating | ShieldSys™ 462S

Price range: $175.03 through $451.72

ShieldSys™ 462S is a high performance silicone conformal coating utilizing exclusive Miller-Stephenson next-generation silicone RTV chemistry. Offering superior protection, toughness, and abrasion resistance while combining the simplicity of a one-part, room temperature cure coating. Conforming to MIL-SPEC 46058C, the applied coating is self-levelling with excellent wet-out, allowing for a very forgiving application process amendable to a wide-range of application configurations without sacrificing coating quality or final film properties. Tack free time is less than 10 minutes. Benefits include:

- High Performance Silicone Conformal Coating

- Excellent Thermal and Abrasion Resistance

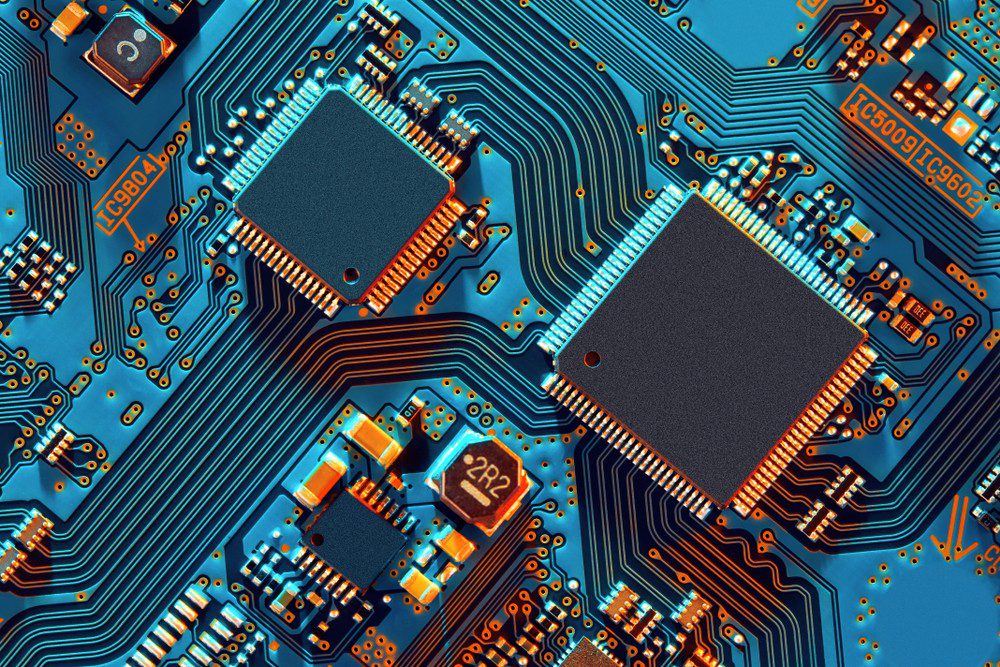

- Ideal for High Vibration, High Moisture, or Heat Challenged PCBs

- Superior Self-Levelling and Excellent Flow-out

- One-Part, Self-Priming, Room Temperature Cure System