No products in the cart.

Epoxy Adhesives EpoxSys™ 300 Series

This product is already in your quote request list.

Category: MS Epoxy Systems

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTMiller-Stephenson’s line of epoxy adhesives are made up of a polymer and a hardener, that when mixed together form an incredibly strong and durable bond that adheres to a wide range of surfaces. Epoxy adhesives are commonly used as industrial adhesives as well as adaptive structural adhesives. Their ability to create a strong, temperature and weather resistant bond makes them ideal for numerous applications.

Applications of epoxy adhesives include:

- Harsh chemical environments such as chemical storage tanks. Epoxies are highly chemical resistant.

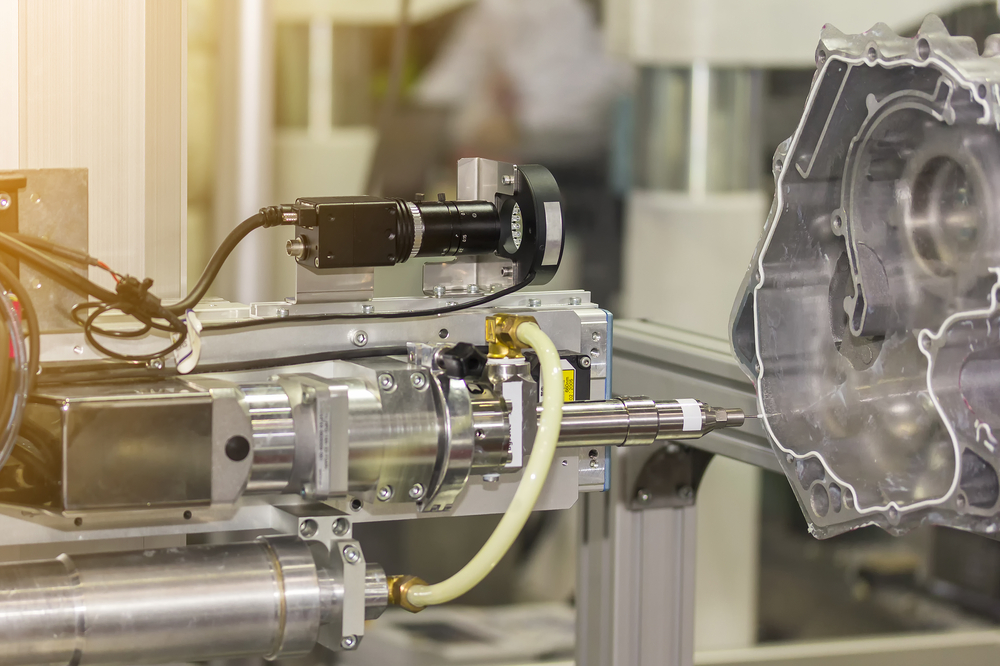

- Automotive sector, as epoxies are extremely strong and low weight. They are increasingly replacing welding as they also dampen vibrations and sound.

- Marine uses, as they are watertight and resist salt and moisture damage.

- Aerospace industry, where epoxy adhesives are commonly used due to their highstrength to weight ratio. Helicopter blades are bound with epoxy adhesives, as they require the extreme strength and mechanical stability of the epoxy.

- Construction industry, where epoxy adhesives are used for their weather and temperature resistance to repair floors and tiles, as well as other outdoor/indoor applications.

Types of Epoxy Adhesives

- DGEBA Epoxy Resin

- Waterborne Epoxy Adhesives

- Epoxy Acrylate Resins

- Flexible Epoxy Resin Glues

- Epoxy Novolac Adhesives

- Room Temperature Curing Epoxy Adhesives

- Sun Curing Epoxy Adhesives

- UV Hybrid Epoxy Adhesives

Benefits of EpoxSys 300 Series

Our line of adhesives offer excellent mechanical properties, with compact and strong chemical structure that yields excellent bonding results. Because the internal tension of our adhesives is small, the shrinkage of the curing volume is kept to a minimum, preventing unnecessary stress points due to shrinkage. The composition of our Epoxies does not contain any contaminants such as alkali or salt, and during curing very low molecular weight volatiles are formed. This allows our adhesives to be incredibly strong, light, and durable, as well as temperature and chemical-resistant.

Considerations when choosing an Epoxy Adhesive:

Different formulas of Epoxy Adhesives should be used for certain applications. In order to ensure the best performance of the adhesive, it is important to use the one that is the best fit for the job. Some considerations for adhesives are:

- Joint and load configurations

When joining pieces using epoxy adhesives, the peel and cleavage should be minimized, while the shear should be maximized. Compression should be maximized, while tensile stress should be minimized. The width of the joint between two parts is more important in securing a bond than the length of the overlap. - Conditions of use

The strength of the bond with epoxy adhesives can be impacted by various conditions such as temperature, chemical exposure, moisture and weather.Adhesives should be tested under the conditions that will be present in their applications before the final selection should be made. - Properties

Rigid and brittle adhesives perform better with heat, chemical resistance, creep resistance and tensile strength. Tough and flexible adhesives work better in impact, peel and thermal shock applications, or surfaces with varying expansion due to heat or moisture. - Method of application

Ensuring the proper production method is also crucial when selecting an adhesive. The method of application and whether the use of one or two part epoxy should be taken into consideration. - Curing speed

Some epoxy adhesives require different curing schedules, and one should consider whether the application is suitable and matches the curing time for a certain epoxy. Many require high temperatures to start the curing process, while others require UV light. Make sure your application can withstand the environments necessary for curing. - Flame and Chemical Resistance

One of the greatest strengths of epoxy adhesives is their resistance to substances such as acids, bases, organic solvents, salt and freshwater, fuels and fluids. Some are more suitable for each of these applications. Epoxies may also be manufactured to meet flame resistance requirements, including the international UL specifications. - Heat and Electrical Conductivity

Epoxies are commonly used to bond materials that must retain their conductivity. Thermally conductive epoxies may be used in applications that promote heat dissipation. Electrically conductive epoxies may be used in applications where electrical connection and discharge of static are necessary.

Epoxy Adhesives are the most commonly used structural adhesives and adhere extremely well to a wide range of surfaces. They can be cured using UV light, high temperatures, and at room temperature. Our line of EpoxSys™ Adhesives is ideal for applications such as metal, concrete, glass, ceramic, plastics, wood and other materials.

Miller-Stephenson is here to help with your epoxy application needs.

The EpoxSys 300 Series for Epoxy Adhesive applications, is one of the many epoxy resin systems offered through the EpoxSys line of epoxy products. Epoxsys products offer a variety of solutions to match a wide range of production and processing needs, so you’ll be sure to find the results you need for a successful result. Contact our sales team today, who will work with you to recommend the right product solution for your application needs. Available through phone, chat, or email your inquiry with the form below.

MS Epoxy Systems

Miller-Stephenson offers a wide range of industrial Concrete Epoxies The EpoxSys™ 1100 series are an excellent line of epoxy resin systems for concrete floor coatings, 100% solids, and overlays. We offer many solutions for concrete flooring environments. Industrial Concrete Flooring Our line of VOC-free epoxy, 100% solids, concrete floor coatings, and overlays is cost-effective and [...]

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTThis product is already in your quote request list.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.