No products in the cart.

Krytox™ Lubricant Articles

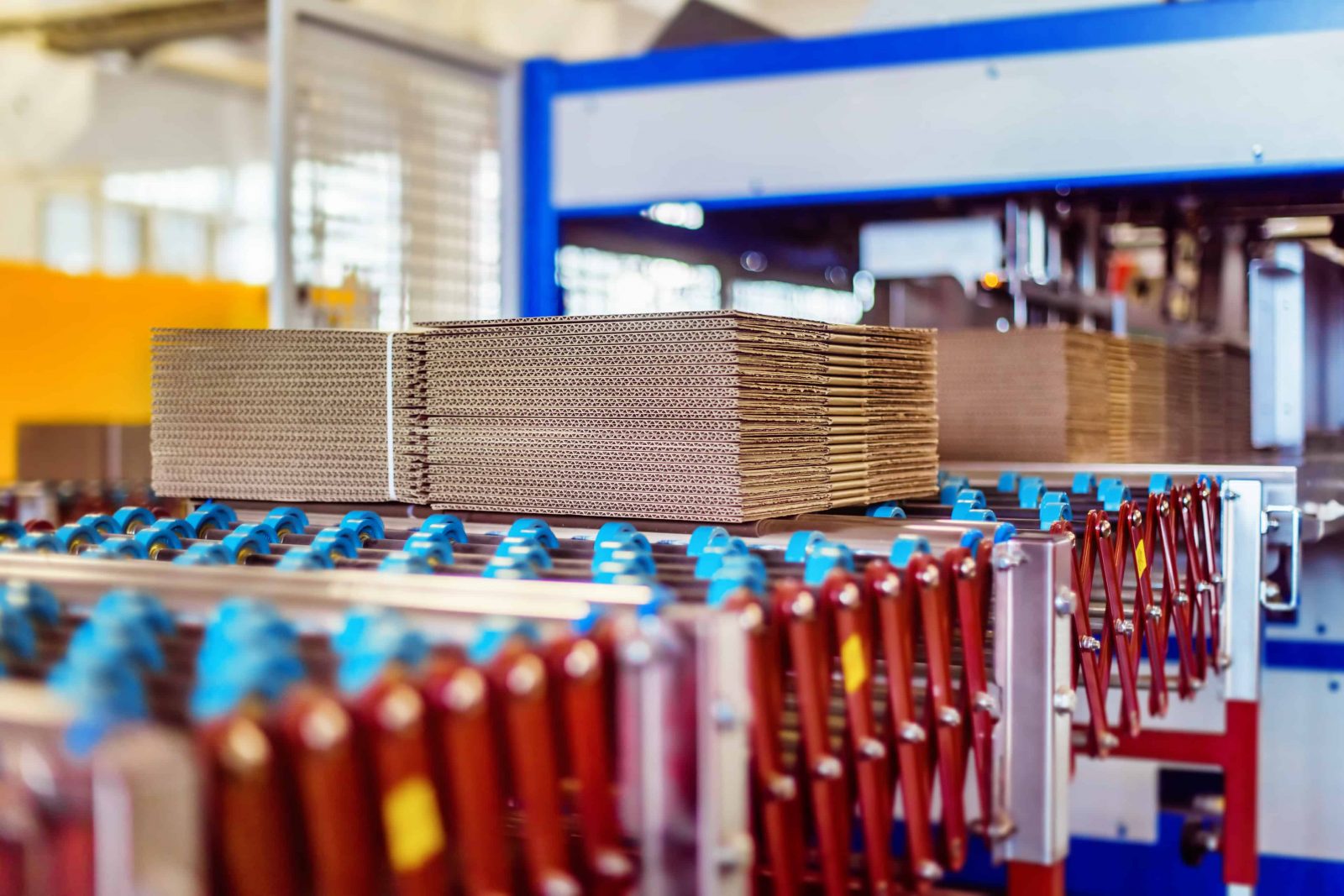

Krytox™ Corrugator Greases

Krytox Corrugator Greases

Product Information

Krytox PFPE/PTFE corrugator greases have become the corrugator industry standard for lubricating bearings on heated rolls in single facers and associated equipment. Krytox lubricants help eliminate bearing lubrication as a cause of premature corrugator roll failures. Corrugator roll changes are significantly easier and quicker on single facers lubricated with Krytox corrugator greases.

Corrugators choose Krytox™ lubricants for many reasons:

- Most productive lubrication system for single facer bearings among all paper corrugating plants, equipment OEMs, and corrugator roll rebuilders

- Most thermally stable H1 base oil available

- Reduced risk of bearing failure

- Conversion support and PFPE lubrication/application training available

Krytox greases for the corrugating industry include:

Krytox Corrugator 226 FG, 227 FG Greases—The standard in PFPE/PTFE greases, recognized by OEMs and operators alike as the premium performing high temperature grease. These products are NSF H-1 Food Grade certified, providing safe, non-toxic, and inert performance in food-related operations.

Safe Handling

For detailed information, refer to the MSDS for the specific grade of Krytox fluorinated grease that you are using. Highlights are:

- When handling, wear any type of impervious gloves.

- Wash hands after use.

- Do not smoke tobacco that may have been contaminated with Krytox grease. Inhalation of fumes from burning Krytox grease may cause a temporary flu-like illness with symptoms such as fever, chills, and sometimes cough. Symptoms are typically gone after 1–2 days.

- When handling Krytox solvent or HC cleaner, use adequate ventilation, and wear eye protection and any type of impervious rubber gloves.

Key Points

- Make sure the bearings are clean and free of preservatives, hydrocarbon oils, greases, and residues before lubricating with Krytox grease; use Krytox HC Plus Cleaner or equivalent. Contaminating Krytox grease with any other lubricant will impair its lubricating value.

- If using pails versus cartridges, slight pooling of oil on top of the Krytox grease can occur, particularly if it has been sitting unused for a while. Simply mix it back in with a clean stirrer.

- Use special grease fittings—pin or button head—for Krytox grease to prevent contamination with hydrocarbon or synthetic lubricants.

- Use a dedicated grease gun (labeled Krytox grease only) with a swivel coupling matched to the special pin or button head grease fittings (bearing inlet ports). Fill the bearings and bearing housings completely to prevent air pockets that can collect water and debris.

- Prevent corrugating process materials (e.g., waxes and paper debris) from entering the bearings.

Relubrication

- Wipe the inlet fittings clean with a clean cloth to prevent contamination of the Krytox grease.

- Add/replenish Krytox™ grease every three months. Pump about 1 lb (1/2 cartridge), or whatever is necessary, of Krytox™ grease into the bearing button or pin head grease fittings to force some existing grease out through the seals. It is best to rotate bearings while adding grease to prevent “channeling” of the new grease through the bearing. A more conservative approach is to follow this practice more frequently, say once a month; proportionately less Krytox grease would be needed. Pay attention to plant safety procedures when working with moving equipment.

- Compare expelled/purged grease with the “Color Guide” and service as noted. (This guide applies to normal wear only; contaminants will alter the grease’s appearance.)

- Wipe off excess Krytox grease from equipment surfaces to prevent buildup of dirt/debris attracted to surface grease.

Disposal and Storage

- Properly dispose of used Krytox grease purged from outlet ports, seals, and/or shaft-bearing clearances according to local, state, and federal codes.

- Keep all Krytox grease containers covered to prevent contamination.

| Color Guide | ||

| Color | Contamination | Recommendation |

| White | None | Grease in good condition: creamy consistency. |

| Gray | 0.0-0.1% iron | Grease in good condition, normal wear in bearing; creamy consistency |

| Tan | 0.0-0.4% iron | Add grease until cavity is full, bearing OK. |

| Brown | 0.0-0.8% iron | Flush bearing with grease until color lightens to tan. |

| Dark Brown | Greater than 0.8% iron | Check bearing for play and noise. If OK, flush/purge with new Krytox™ grease. If not OK, schedule bearing change. |

| Black | Replace bearing. |

To learn more about Krytox corrugator greases please contact us by clicking here.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.