Food Grade Lubricant | Miller-Stephenson Food Industry’s Food Grade Lubricant Krytox™ performance lubricants are the golden standard within the food industry. Some Krytox lubrication grades meet NSF H-1 certification for incidental food contact and assist in machinery longevity, requiring less maintenance, and produces quality end products. Krytox™ food grade lubricant deliver superior lubrication that provides […]

Category Archives: Krytox™ Lubricant Articles

Application based articles from Chemours regarding Krytox.

Krytox™ | Conveyor Belt Lubricants Save money with Krytox™ conveyor belt lubricants Krytox™ performance lubricants are the golden standard for lubricating bearings used in the corrugated packaging industry. Krytox conveyor belt lubricants assist in machinery longevity, requiring less maintenance and produces quality end products. Krytox™ lubricants deliver superior lubrication that provides a highly effective and […]

Krytox™ XHT-1000 Oil | Thermowell Probe Lubricant Thermowell probe end-user finds Krytox™ XHT-1000 Oil as a heat transfer fluid inside thermowell chamber A thermowell probe end-user was looking for a thermowell probe lubricant that can fill the small air gap between the thermowell sheath and temperature probe, withstand high-heat, reduce temperature inaccuracies, increase temperature reactivity […]

Krytox™ GPL-105 Handpiece oil | Reduces Dental Handpiece Wear and Chatter Dental equipment and supply manufacture finds an H1 lubricant to reduce dental drill turbine maintenance and save money A manufacturer of high-end dental equipment and supplies wanted to utilize high performance, H1 lubricant for the inside of their dental handpieces to reduce maintenance costs […]

Labeling Machine Gearbox Lubricant Application Bottling plant in Britain eliminates oil leakage problem A British bottling plant of a popular soft drink was experiencing major problems with oil leakage and oil oxidation in its labeling machine gearbox, causing significant unscheduled downtime. Krytox GB series gearbox lubricant helped provide a solution. Because of the equipment layout […]

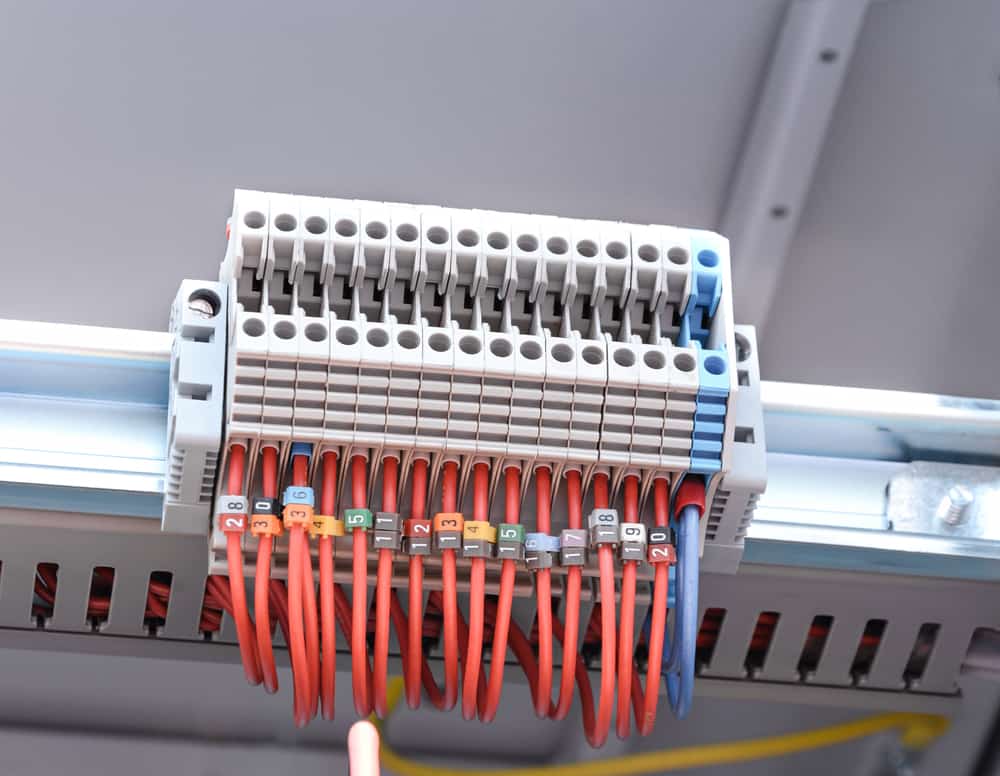

Lubricant & Sealant for Electrical Connectors Krytox™ TS4 sealant and electrical connector lubricant are designed as an ultra-low oil separation sealant and lubricant specifically for static applications. Krytox™ TS4 can be used for high temperature, non-reactive, non-flammable, and non-oxidative sealant applications, such as vacuum and pressure systems, electrical connections, transformer gaskets, equipment enclosures, and pipe […]

Military Specification Lubrication | Mil-Spec Lubrication A United States defense standard, often called a military standard, “MIL-STD“, “MIL-SPEC“, or (informally) “MilSpecs“, is used to help achieve standardization objectives by the U.S. Department of Defense. Standardization is beneficial in achieving interoperability, ensuring products meet certain requirements, commonality, reliability, the total cost of ownership, compatibility with logistics systems, and similar defense-related objectives. Specialized MIL-Specs (MIL-PRF-27617) were […]

Radiation Stability of Krytox™ and Fluoroguard™ Polymer Additives The results of some radiation stability exposure data obtained on our Krytox™ 143AB fluorinated oil and Krytox™ 240AB fluorinated grease that contains this oil are summarized in Tables 1–4. It is believed that these data are generally representative of the performance of all Krytox™ oils and greases. […]

How To Work With Your OEM To Find The Best Lubricant Nothing is as Expensive as Cheap Lubricant As a plant operator, there’s a lot to manage. Ensuring that the plant is functioning at optimum levels requires management prowess, people skills and broad-based technical knowledge. Increasingly, as machines run hotter and environments get more extreme, […]

How Manufacturers Have Reduced Downtime and Costs | PFPE Lubricant | Krytox From equipment selection to maintenance cycles and troubleshooting, we know you work tirelessly to achieve peak plant performance every day. With the average plant using more than 2,000 bearings – in addition to the valves, seals and other PFPE lubricant reliant components – […]