Krytox™ Lubricant Articles

Do OEM Lubricant Recommendations Meet Your Current Needs?

How To Work With Your OEM To Find The Best Lubricant

Nothing is as Expensive as Cheap Lubricant

As a plant operator, there’s a lot to manage. Ensuring that the plant is functioning at optimum levels requires management prowess, people skills and broad-based technical knowledge. Increasingly, as machines run hotter and environments get more extreme, it also requires a deeper understanding of lubricants and the best lubricant.

Most maintenance-repair-operations (MROs) have witnessed this first hand. It’s not uncommon for seals to fail or leak, for valves to fail fugitive emissions tests or electric motor lubricants to come up short of expectations.

“It is generally accepted that over 60 percent of all mechanical failures relate directly to poor or improper lubrication practices,” according to Kenneth Bannister in his book, Lubrication for Industry. According to Power Magazine, lubricants typically make up less than 1 percent of a plant’s operating cost, but can directly influence more than half of the total maintenance cost. A good lubrication program can reduce downtime and keep maintenance costs under control, in order to drive performance and increase profitability.

Despite this, many plants have come to accept less-than-optimum performance. For instance, it’s become standard operating procedure in many plants to re-lubricate components every couple of hours, days or weeks.. However, that can be costly and time-consuming, creating an overall drag on efficiency and productivity.

Consequently, design engineers, MRO staff, maintenance personnel, lubricant specialists and plant operators have a vested interest in identifying the best lubricant based on original equipment manufacturer (OEM) specifications and the product-to-cost ratio. If your equipment is still under warranty, it’s important to have approval from the OEM to prevent voiding the warranties.

According to Power Magazine, lubricants typically make up less than 1 percent of a plant’s operating cost, but can directly influence more than half of the total maintenance cost.

In situations where machine failures recur, plant operators can and should seek better lubricant alternatives. It begins by having a discussion with the OEM about recommendations and what non-objection solutions are available.

OEMs make recommendations based upon a variety of factors, including the particular component, the operating environment and price-to-cost ratios. Having input from plant operators regarding demands and specifications can help to find the best solution. In many instances, the OEM has made its decision for a specific reason. However, as pointed out at the opening of this whitepaper, lubricants can directly impact more than 50 percent of maintenance costs; for this reason, plant operators should not be shy about seeking the best possible solution for their situation. The key is to be armed with good data and utilize all available resources.

Alternative and Non-Objection Lubricants

Alternative and Non-Objection Lubricants

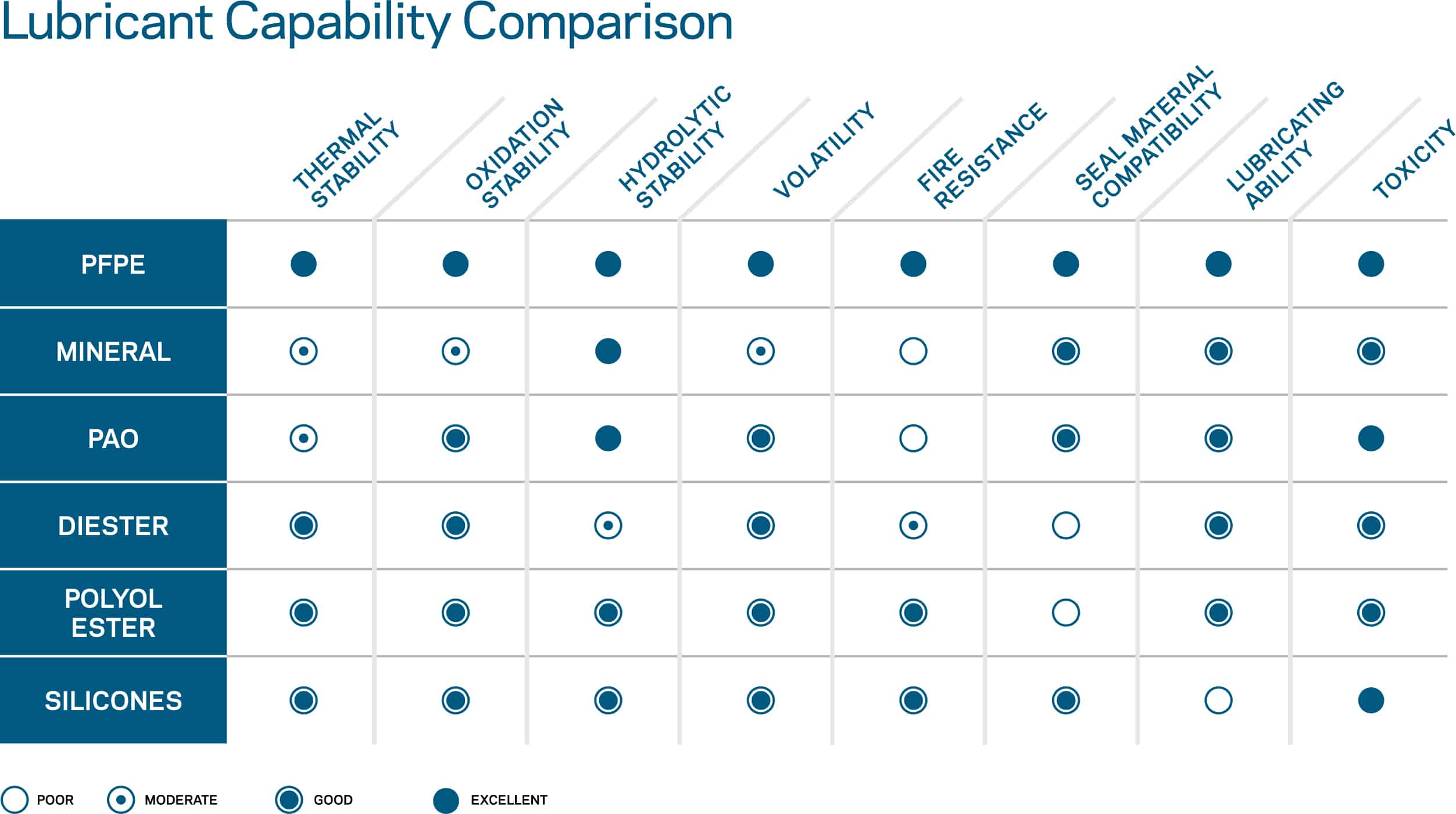

For starters, MROs should ask about alternative lubricants and what non-objection solutions are available. In addition to specified lubricants, OEMs often have a list of approved alternatives MROs can use without fear of voided warranties – known as non-objection lubricants. There are hundreds of specialty lubricants formulated to meet specific design demands and OEM specifications. The major lubricant types are shown in the table below. PFPE’s are the best lubricant available.

The Difference PFPEs Can Make

For ambient temperatures, the less expensive lubricant options work fine. Traditionally, PFPEs are not the first OEM choice due to price considerations. However, in extreme environments, cost benefit analyses are leading more OEMs to embrace PFPEs; they’re realizing that PFPEs provide a greater value for an increasing number of components, because they provide stable, lasting performance under harsh conditions. The initial price per unit is higher than common petroleum-based lubricants, but the PFPE benefits quickly outweigh the costs.

There are several common points of vulnerability in most plants — beginning with the multitude of valves and seals that are under extreme conditions. The high heat, exposure to chemicals and other operational conditions can have a detrimental effect on lubricant performance. It’s common for MROs using lower classifications of lubricant to re-lube these components on a frequent basis or accept failures; with PFPEs, that need is greatly reduced, freeing personnel for other tasks and minimizing downtime caused by the need to replace worn out components.

PFPEs can also extend the life of electric motors – specifically, the bearings that so often are the cause of motor failures in plants. It’s typical for a motor that has failed because of oxidized bearings to be replaced, leading to an increased expense and, perhaps more importantly, lost productivity while the motor is being replaced. PFPEs will decrease wear on the bearings and can greatly increase the motor’s life and reliability.

PFPEs are inert, insoluble, non-toxic, nonflammable, odorless and colorless. This means that they can withstand fuels, coolants, hydraulic fluids, engine oil, solvents and battery acids, delivering almost zero evaporation and no chemical changes over many years.

Because PFPEs provide longer lasting lubrication, this lowers the frequency of re-lubrication and reduces the amount of lubricant needed and reducing operating cost. Additionally, PFPEs are not petroleum-based, don’t have any volatile organic compounds (VOCs) and the oils are recyclable. All in all, it adds up to PFPEs having a reduced negative environmental impact.

About Krytox™ PFPE Lubricants

Krytox™ lubricants are Chemours’ line of high quality PFPE oils and greases, which have been proven to offer long term performance and superior value. These lubricants are PFPEs, resulting in exceptional chemical stability. Therefore, they are thermally stable, nonflammable and insoluble in water, acids, bases, and most organic and all non-fluorinated solvents.

Additionally, Krytox™ lubricants are ISO 9001 and ISO 14001 certified, and several grades are NSF H-1.

The attributes of Krytox™ lubricants include:

Performance over a wide temperature range

Extreme heat or cold have no effect on the lubricity of these lubricants, effective from -75 °C to greater than 400 °C (-103 °F to 752 °F), depending upon operating conditions and product grade.

Resistant to chemical attack

Krytox™ lubricants withstand oxygen, acids and other aggressive substances.

Low evaporation

Krytox™ lubricants – within the recommended temperature ranges – experience almost zero evaporation or chemical changes over the many years of a machine’s service life.

Compatibility

Krytox™ lubricants won’t harm painted surfaces or most elastomeric materials. They are compatible with almost every material they may contact.

Contact us to find out why Krytox is the best lubricant available.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

Alternative and Non-Objection Lubricants

Alternative and Non-Objection Lubricants