Krytox™ Lubricant Articles

Radiation Stability of Krytox™ and Fluoroguard™ Polymer Additives

Radiation Stability of Krytox™ and Fluoroguard™ Polymer Additives

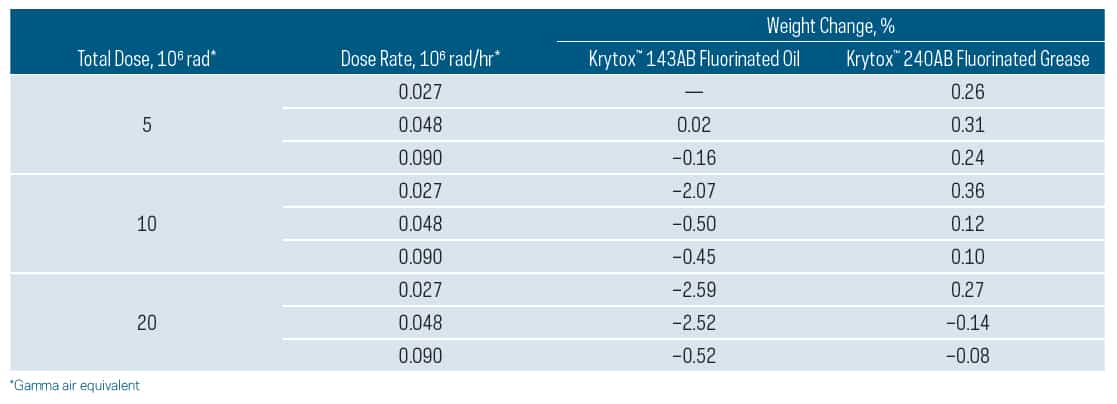

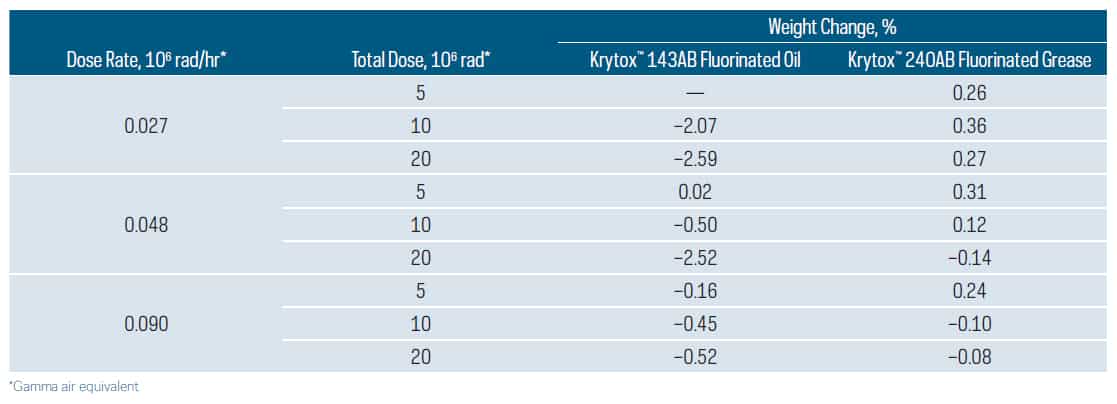

The results of some radiation stability exposure data obtained on our Krytox™ 143AB fluorinated oil and Krytox™ 240AB fluorinated grease that contains this oil are summarized in Tables 1–4. It is believed that these data are generally representative of the performance of all Krytox™ oils and greases.

Samples of oil and grease, in tin-plated screw-cap metal cans, were exposed to a Cobalt-60 source. Rates and total dosages (gamma air equivalent) were varied as indicated, and each data point represents a separate

sample.

Radiation of these fluoropolymers can result in de-polymerization to volatile or, at least, lower molecular weight fragments. Some of these radiation products would be expected to be acidic. In fact, some evidence

for corrosion of the metal containers was observed, but it was very minimal and random.

Following the prescribed total dosage exposure, the samples were removed from the radiation field and re-weighed to determine weight losses. These are reported both as a function of total dosage (Table 1) and

as a function of rate (Table 2).

Table 1. Radiation Stability of Krytox™ 143AB Fluorinated Oil and Krytox™ 240AB Fluorinated Grease Cobalt-60 Source Weight Change versus Total Dose and Dose Rate

Table 2. Radiation Stability of Krytox™ 143AB Fluorinated Oil and Krytox™ 240AB Fluorinated Grease Cobalt-60 Source Weight Change versus Dose Rate and Total Dose

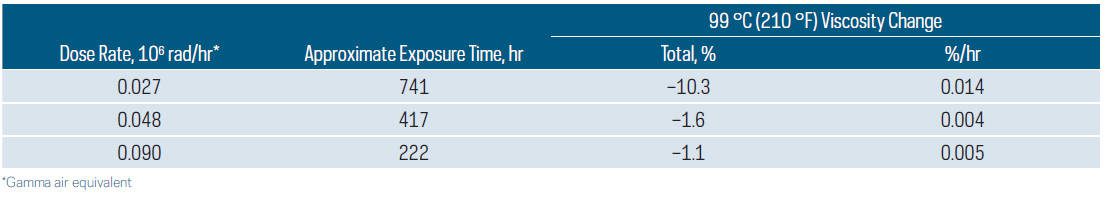

In addition to weight change, the viscosity change of radiated Krytox™ 143AB fluorinated oil was measured. These samples were vacuum stripped to remove any “light ends.” The percent viscosity change is summarized in Table 3 for a total dosage of 20 x 106 rad.

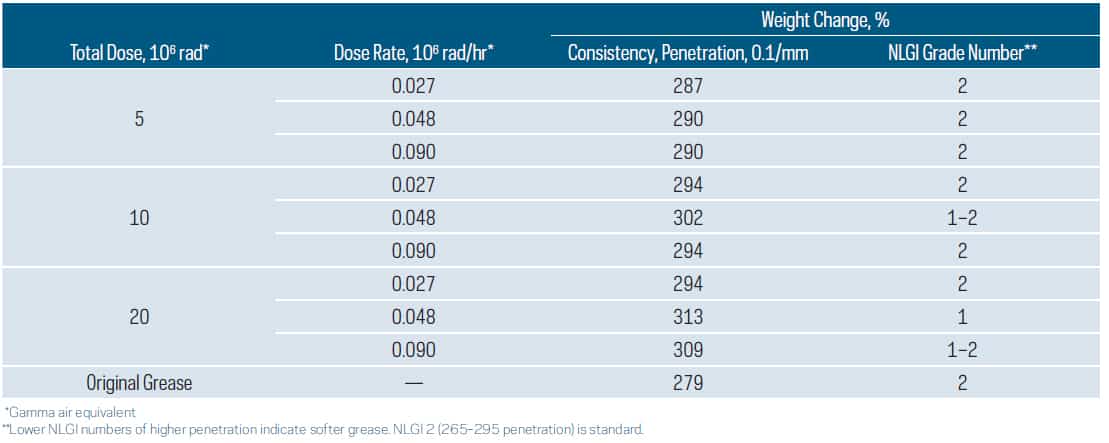

Grease consistency, as determined by penetration measurements, was obtained on the radiated and original grease samples. While there was some minor softening of the grease, it was not considered to be significant and would not be expected to impede its performance. These data are summarized in Table 4.

Table 3. Radiation Stability of Krytox™—Effect on Viscosity of Krytox™ 143AB Fluorinated Oil Cobalt-60 Source Total Dose 20 x 106 rad*

Table 4. Radiation Stability of Krytox™—Effect on Consistency of Krytox™ 240AB Fluorinated Grease Cobalt-60 Source

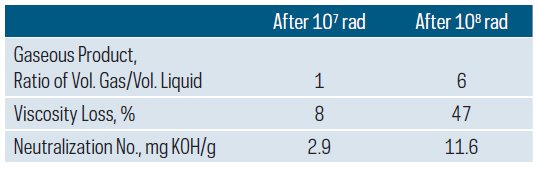

Radiation stability was evaluated in a nuclear reactor at 107 and 108 rad total doses. Only a minor change occurred at 107 rad, while a significant change in viscosity and acidity was observed at 108 rad.

The oil was subjected to a mixed dose of gamma as well as thermal and fast neutrons. The exposure in both tests was at the core face of the reactor. A dose of 107 or 108 rad of reactor radiation is probably considerably more severe than the same dose of pure gamma radiation.

All Krytox™ PFPE fluorinated oils and Fluoroguard™ polymer additives are chemically identical. They differ in average molecular weight and molecular weight distribution. The property changes shown for Krytox™

143AC, 143AB, and 240AB are believed representative of all Krytox™ fluorinated oils and greases. This would include the 143 series oils, 240 series greases, GPL 10X series oils, the GPL 20X series greases, Fluoroguard™ polymer additive oils—PCA, SG, and PRO, LVP grease, XHT series greases, Krytox™ 1500 and 1600 series PFPE vacuum pump fluids, Krytox™ FG H-1 rated food oils and greases, K fluids, and other PFPE products.

Table 5. Krytox™ 143AC Typical Properties

The Krytox™ 240AB grease consists of a 76 cSt PFPE oil with PTFE thickener. The 143AB oil is 76 cSt and the 143AC oil is 240 cSt at 40 °C (104 °F). For this test, the reactor operating at full power gave a dose of 107 rad in 83 min (at the core face). The thermal neutron flux was 2 x 1012 neutrons/cm2·sec, the fast neutron flux was 1 x 1012 neutrons/cm2·sec, and the gamma dose was 1.6 x 107 R/h.

The Krytox™ 240AB grease consists of a 76 cSt PFPE oil with PTFE thickener. The 143AB oil is 76 cSt and the 143AC oil is 240 cSt at 40 °C (104 °F). For this test, the reactor operating at full power gave a dose of 107 rad in 83 min (at the core face). The thermal neutron flux was 2 x 1012 neutrons/cm2·sec, the fast neutron flux was 1 x 1012 neutrons/cm2·sec, and the gamma dose was 1.6 x 107 R/h.

For more information call us or contact us.

Krytox™ is a trademark of The Chemours Company FC, LLC.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.