Miller-Stephenson Articles

Composite Mold Release Agents | ReleaSys™

Composite Mold Release Agents – ReleaSys™

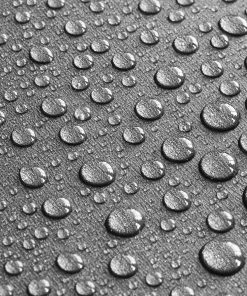

Miller-Stephenson Composite mold release agents are backed by over 40 years of technical experience and are trusted to deliver the most consistent release of composite material in the industry. Our formulations are uniquely tailored to yield unmatched utility to the constantly evolving composite industry. ReleaSys Composite mold release agents use advanced crosslinking chemistry to create a low surface energy film which exhibits high slip, superior chemical and thermally durability. Large and small manufacturers can expect higher productivity and profitability through reduced downtime, increased acceptance rates and improved part quality when switching to Miller-Stephenson’s ReleaSys semi-permanent line. With our composite mold release agents operators will see minimal transfer to molded components, low clogging, and easy application. As a leader in the development of water-based products, Miller-Stephenson offers environmentally conscious technology for composite molders who require the same, uncompromised high levels of quality and performance as found in traditional solvent-based products.

Benefits of ReleaSys™ Composite Mold Release Agents

- Low or No volatile organic compounds (VOC)

- Minimal odor; 100% Non Flammable Solvent based Formulations

- Ultra High Performance Water based Formulation

- Semi- ermanent and Sacrificial Coatings

- Higher productivity; Increased cost-effectiveness

- Low rejection rate; Consistent part quality

Applications of ReleaSys™ Composite Mold Release Agents

Miller-Stephenson composite mold release agents have been optimized to cover industry applications from Fiber Reinforced Plastics (FRP) to advanced composites. Aerospace, automotive, construction, marine, recreational/sporting goods, wind energy and more all benefit from ReleaSys. ReleaSys™ release agents provide exceptional utility, improving molding processes such as vacuum bagging, resin fusion, layup and etc. Our products are applicable in all manufacturing process such as:

- Thermoset Epoxies, Phenolics, and BMIs

- Thermoset Prepregs

- Potting and Casting Resins

- Hand lay ups

- Filament Winding

- Autoclave molding

- Vacuum bag molding

- Resin transfer molding

- Resin film infusion

- Compression, Transfer, Injection Molding

- Rotational Molding

- Metallic, Ceramic, and Composite Tooling

ReleaSys™ Composite Mold Release Agents

Miller-Stephenson combines great technical and industry knowledge with a hands on approach to service and support to address the challenges faced by our customers in their composite molding operations. Beyond the basics of releasing finished parts from their molds, utilizing our product line of ReleaSys™ semi permanents mold release agents and PTFE Dry Film release agents, along with our industry leading support network, brings significant operational benefits.

- Water based options for reducing environmental impact and improving facility HSE

- Flexibility to accommodate a wide range of process conditions

- A global network of support experts to work with you

- Cost effective, high durability, and consistent mold release

- Reduced downtime and scrap rates

- Minimal mold fouling and transfer

Composite Mold Release Agents Selection Guide:

Product Type | Application | Finish | Product | Description |

| Solvent / Semi-Permanent | Compression Molding, Casting, Vacuum Bagging | Matte-Satin | ReleaSys 8900 | Highest Release |

| Minimal transfer; No Build up | ||||

| Fast Cure (3-5min @ 50 °C) | ||||

| Water-Based / Semi-Permanent | Compression Molding, Casting, Vacuum Bagging | Matte | ReleaSys 9900 | Medium Slip |

| No transfer; No Build up | ||||

| Instant Cure | ||||

| PTFE Dry Film | Resin Potting and Casting | Matte-Dry | ReleaSys DF or ReleaSys 8200 | PTFE Dry Film |

| No transfer | ||||

| Minimal Rejection Rate | ||||

| High Durability | ||||

| Water-Based / Semi-Permanent | High Slip | Matte | ReleaSys 8800 | Instant Cure |

| Minimal transfer | ||||

| High Durability; High Slip | ||||

| Solvent / Semi-Permanent | Filament Winding | Matte-Satin | ReleaSys 7200

| High Release |

| Zero transfer; No Build up | ||||

| Instant Cure | ||||

| Solvent / Semi-Permanent | High Performance Composites | Matte-Satin | ReleaSys 8900 | Highest Slip |

| Minimal transfer; No Build up | ||||

| Fast Cure (3-5min @ 50 °C) |

Technical or Application Support:

- For any questions about proper application of our mold release products please view our article which discusses this process

- Technical or application support please contact our tech staff

- ReleaSys and ShieldSys Product Selection Guide

The recommendation made here with and the information set forth with respect to the performance or use of our products are believed, but not warranted to be accurate. The products discussed are sold without warranty, as to fitness or performance, express or implied and upon condition that purchasers shall make their own test to determine suitability of such products for their particular purposes. Likewise, statements concerning the possible uses of our products are not intended as recommendations to use our products in the infringement of any patent.