No products in the cart.

Krytox™ Lubricant Articles

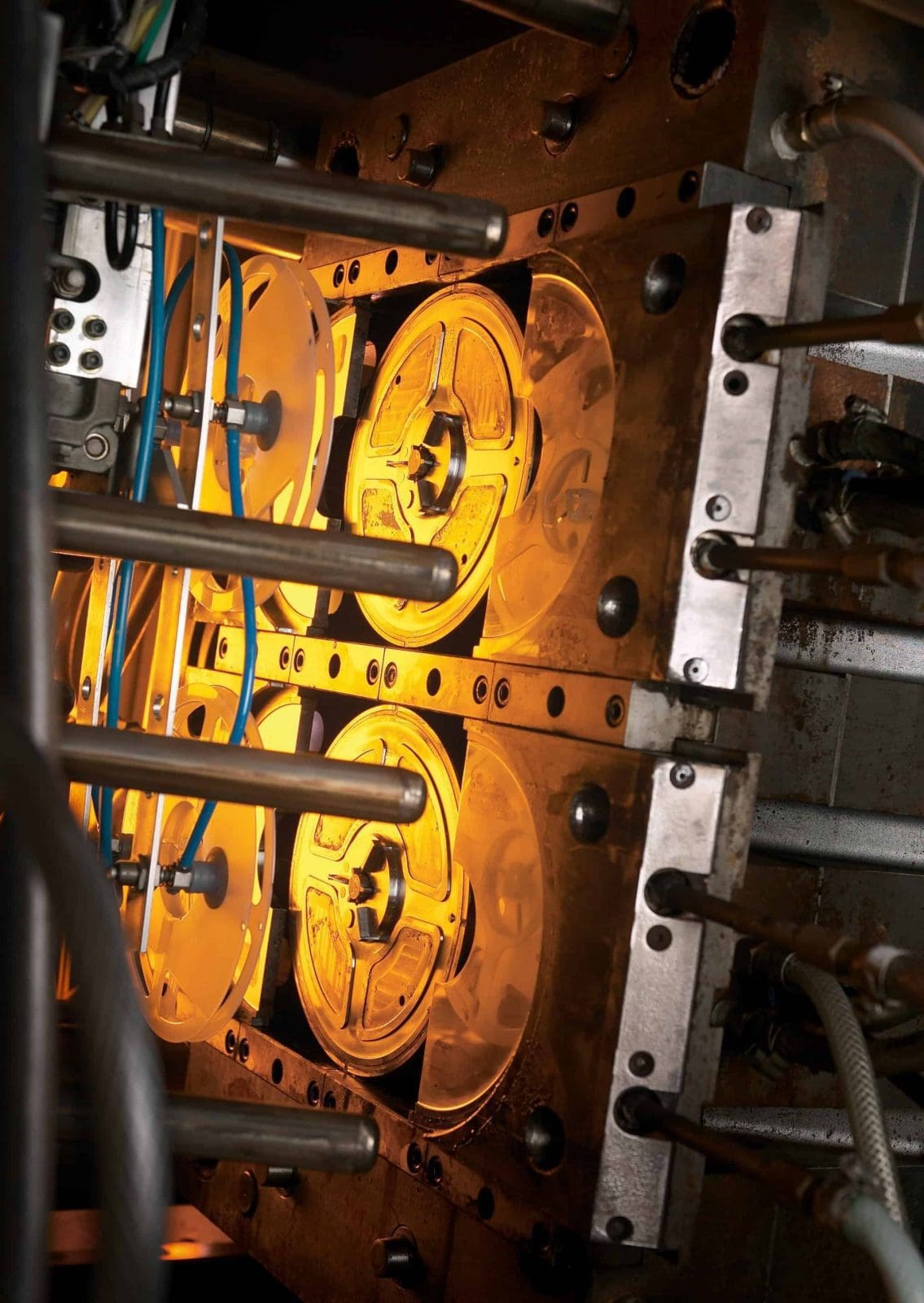

Krytox™ for Injection Molding

“We have been using Krytox XHT-BDX for seven years now. We did a case study, and found out that we gained an additional 40% life between preventative maintenance (PM’s).” – A satisfied Krytox customer

The Problem

The Injection Molding industry for Tier 1 auto suppliers require hundreds of man hours in preventative maintenance labor. Not using Krytox results in:

- High labor costs

- Contaminated parts

- More frequent preventative maintenance

The Solution

Krytox lubrication has been designed and demonstrated to provide the best available equipment performance and lowest available life cycle cost. Krytox XHT-BDX delivers:

- Maintenance and capital savings

- Increased life cycle between maintainence

- Does not migrate to the surface or wick out

- Extreme heat tolerance / Doesn’t thin

The Application

- Lifters

- Slides

- Ejector Pins

- Retractors

Demonstrated Solutions

For over 20 Years Krytox has provided state-of-the-art performance for mechanical systems under harsh conditions. From gearboxes, bearings and chains to seals, actuators, valves and more Krytox serves the specialized needs of:

- Pulp and paper mills

- Automotive Components

- Military and commercial aircraft

- Chemical plants

- Power plants

- Turbine generators

- Other critical industrial applications

Krytox™ is a trademark of The Chemours Company FC, LLC.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.