No products in the cart.

Vertrel SFR Chemours Solvents

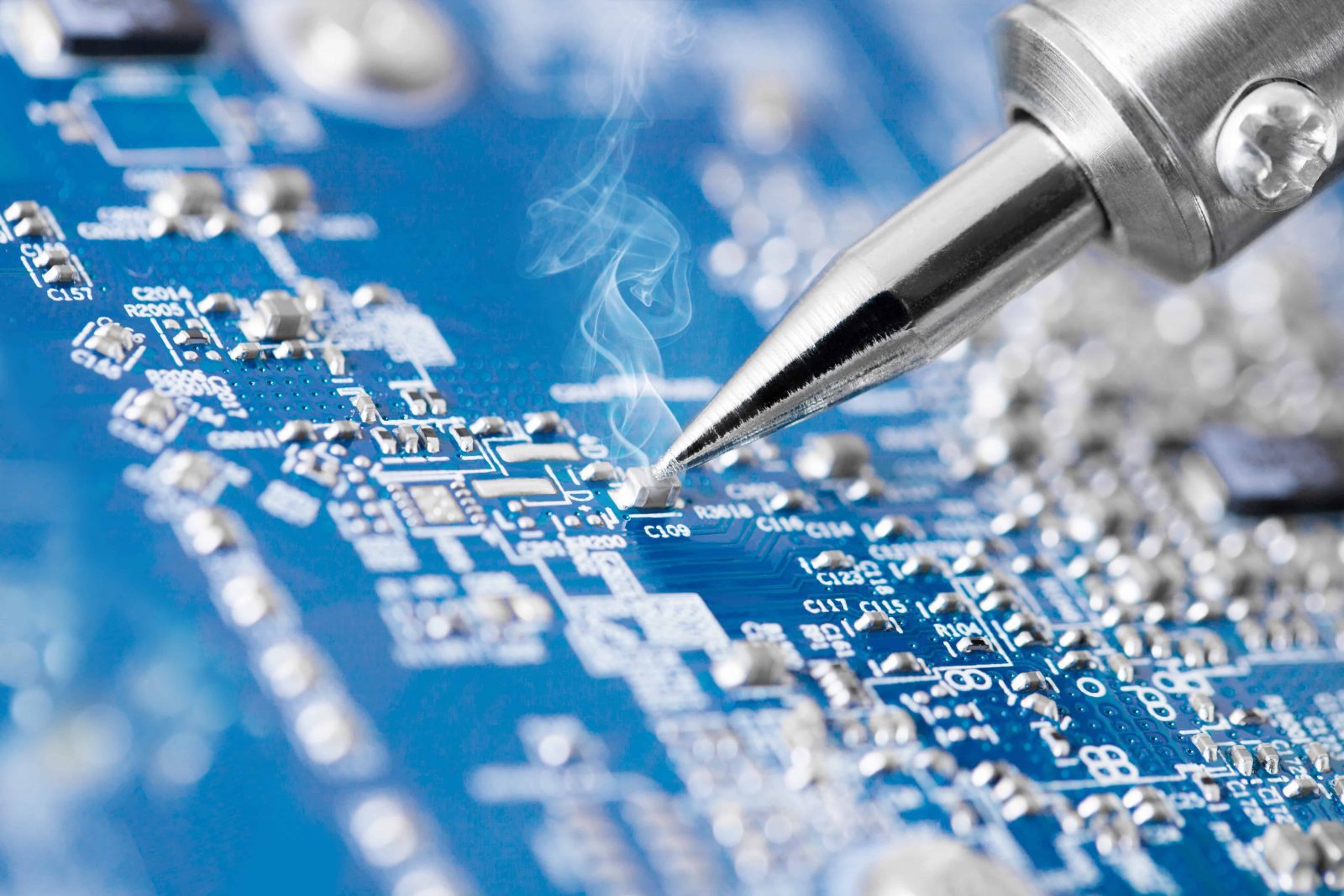

Vertrel SFR specialty fluid can solve your most difficult defluxing needs, designed specifically for cleaning in lead-free and no-clean solders. It has excellent solvency power for a wide range of soils including ionics. As a replacement for n-propyl bromide (nPB) in most circuit cleaning applications, Vertrel SFR Flux Remover is an excellent choice. It carries a moderate global warming potential and medium VOC content. Vertrel SFR balances performance with favorable environmental and worker safety properties.

This product is already in your quote request list.

Category: Vertrel™ Solvents

Tags: Degreaser, SFR, Solvent, Vertrel

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTVertrel SFR Chemours Solvents | Lead Free and No Clean Flux Removal

Engineered for Maximum Solvency of Stubborn Fluxes, Solders, and Ionic Contaminates

Vertrel SFR is an engineered mixture of nonflammable hydrofluorocarbons (HFCs), trans-1,2-dichloroethylene (t-DCE) and methanol. Designed to solvate difficult to remove high temperature fluxes used in lead free and no clean solders. It has excellent solvency power for a wide range of soils including ionic soils. The low surface tension and nonflammable properties of Vertrel SFR make it an ideal ultrasonic vapor degreasing solvent. SFR specialty fluid can solve your most difficult defluxing needs used in lead-free and no-clean solders. It has excellent solvency power for a wide range of soils including ionics. As a replacement for n-propyl bromide (nPB) in most circuit cleaning applications, this Flux Remover is an excellent choice. It carries a moderate global warming potential and medium VOC content. Vertrel SFR is a non-ozone depleter and can replace many solvents such as trichloroethylene (TCE), n-propyl bromide (nPB), HCFC-225 blends, HCFC-141b, HFEs, PFCs, and CFCs. Vertrel SFR can also replace aqueous cleaners where floor space and cleanliness are at a premium.

Features and Benefits of Vertrel SFR

Vertrel SFR balances performance with favorable environmental and worker safety properties.

- Excellent solvency power (KB Value>100) to remove organic and ionic contaminants: Superior cleaning performance

- Fast drying: Increases productivity

- Low surface tension: Able to penetrate and clean tight areas

- Compatible with most plastics, elastomers, and metals

- Can be used with ultrasonics.

- Non flammable

- Low toxicity

- Zero ozone depletion potential

- Low global warming potential

- Existing equipment can be used with minor or no modification

- No surfactants needed: Residue free cleaning is promoted.

Typical Applications for Vertrel SFR

- Defluxing

- Oil, grease, and wax removal

- Precision Cleaning

Specification Conformity Tests

Vertrel SFR has been tested in a variety of industrytests, including:

Boeing D6-17487 Revision P

Solvent Cleaners; General Cleaning

ARP 1755 B

Effect of Cleaning Agent on Aircraft Engine Materials

Douglas Aircraft Company

Type 1: Materials and Procedures for General Exterior Cleaning of

Painted and Unpainted Surfaces. (General Purpose Cleaner)

Environmental Properties of Vertrel SFR

Vertrel SFR has zero ozone depletion potential and low global warming potential. Vertrel SFR is accepted by the US Environmental Protection Agency under the Significant New Alternatives Policy (SNAP) program as a substitute for ozone-depleting substances (solvent category). It is not SNAP approved for aerosol packages.

Safety/Flammability/Storage

Data from acute toxicity studies has demonstrated that Vertrel SFR has low toxicity. It has a calculated AEL (Acceptable Exposure Limit) of 187 ppm based on its individual components. AEL is an airborne inhalation exposure limit established by Dupont that specifies time-weighted average concentrations to which nearly all workers may be repeatedly exposed without adverse effects. The calculated AEL is in accordance with ACGIH formulas for TLVs for mixtures. Vertrel SFR is a slight skin and eye irritant and has low acute inhalation toxicity. Please refer to the MSDS for information on detailed exposure limits and toxicity-related data.

Vertrel SFR exhibits no closed cup or open cup flash point and is not classified as a flammable liquid by NFPA or DOT. The product is volatile, and if allowed to evaporate and mix with air, the vapor may become flammable. Vertrel SFR is thermally stable and does not oxidize or degrade during storage. Store in a clean, dry area. Protect from freezing temperatures. If solvent is stored below –10 °C (14 °F), mix prior to use. Do not allow stored product to exceed 52 °C (125 °F) to prevent leakage or potential rupture of container from pressure and expansion.

Material Compatibility

Most metals, plastics and elastomers commonly used for components mounted on printed wiring board assemblies can be safely cleaned with Vertrel SFR. Plastics that may show signs of softening, swelling or other changes include acrylics, ABS and polycarbonate. Elastomers, if affected, will generally revert to within a few percent of original size after air-drying. Prior-to-use, testing of plastics and elastomers should be performed under conditions expected during normal operation (e.g., time in contact with SFR, temperature, etc.). For more information on material compatability, contact Miller-Stephenson. Contact with highly basic materials, pH 10 and above, is not recommended. Large amounts of water may extract the alcohol component of Vertrel SFR, and reduce cleaning performance. Therefore, to reduce alcohol loss, use desiccant dryers rather than water separators in the condensate return line.

Miller-Stephenson – An Industrial Leader in Critical Cleaning

Miller-Stephenson started producing aerosols to clean electronics. Today, our mission has expanded to include cleaning answers that utilize the industry’s most innovative technologies. Miller-Stephenson has optimized clean solutions, and collaborates with equipment makers around the world. Customers can have cleaning studies with Miller-Stephenson fluids performed at no charge in our state-of-the-art applications laboratory. Our “best-practices” approach to critical cleaning makes Miller-Stephenson products more cost-effective than any competing technology. Lastly our product stewartship provides a complete solution, from choosing the right solvent through implementation with an emphasis on safety and environmental regulations.

To learn more about Vertrel™ and its ability to remove nPBs please click here.

Click here to learn more about Opteon Sion and vapor degreasing.

Vertrel™ is a trademark of The Chemours Company FC, LLC

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

Vertrel SFR PDF

(pdf, 864KB)

Technical Data Sheet

- Defluxing

- Medium and Heavy Soil Removal

- Light Soil Removal

- Precision Cleaning

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

| Aerosol | Glass | Pail |

| 8 oz. | Quart. | 5 Gallons |

| 12 oz. | 1 Gallon | 55 Gallons |

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.