No products in the cart.

Duster Spray | MS-222N AeroDuster®

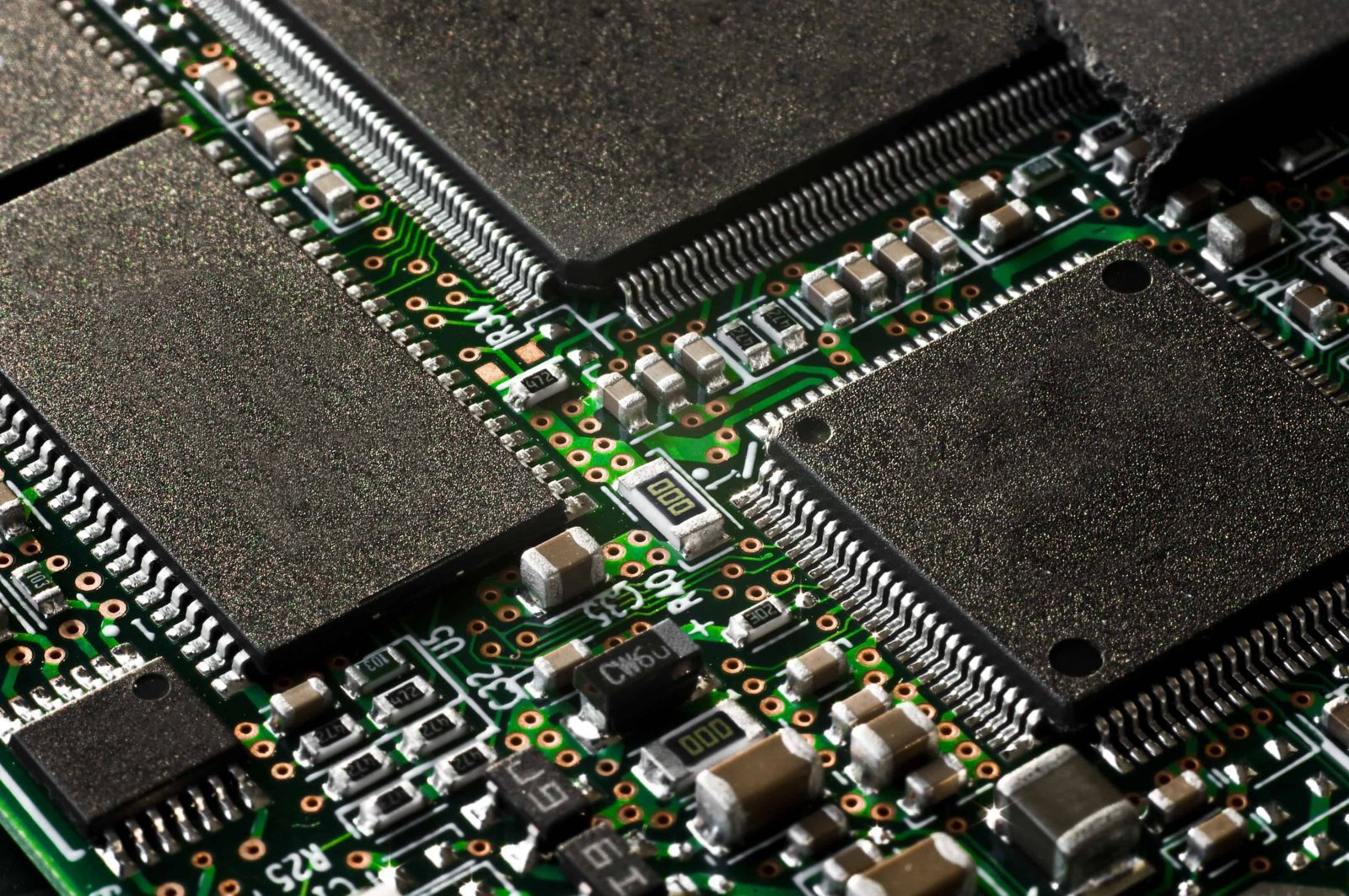

MS-222N AeroDuster® duster spray is a nonflammable, ultra pure compressed air propellant which is used to rapidly remove dust from sensitive electronics, optics, and other specialty equipment. It is non conductive and leaves no unwanted residue. Additional product benefits include:

- Nonflammable and Non-abrasive

- Non-conductive

- Odorless

- Leaves no traces of contaminates and oils

This product is already in your quote request list.

Category: Specialty Products

Tags: Aero, Duster, MS-222L, MS-222N

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCTDuster Spray | MS-222N AeroDuster®

Ideal For Electronics, Leaves No Traces of Contaminates and Oils, 100% Nonflammable

Miller-Stephenson’s AeroDuster® MS-222N Duster Spray is a nonflammable, ultra pure compressed air propellant which delivers a dry blast of air to remove microscopic dust in numerous applications in areas of electronic, photographic, computer, and other energized electrical equipment. MS-22N Aero-Duster® is a pure product with no traces of contaminates and oils, which is essential for critical applications. MS-222N Aero-Duster® available in (14oz Aerosol) and MS-222T (10oz Aerosol) cans.

AeroDuster® MS-222N Duster Spray Advantages:

- Nonconductive

- Nonflammable, Odorless

- Low Toxicity, Leaves no residue

- Compatible with most plastics, elastomers, and metals

- Convenient packaging

- RoHS2 and RoHS3 compliant

AeroDuster® MS-222N Duster Spray Removes Microscopic Dust From Energized Electrical Equipment Such As:

- Semiconductor chips

- Specimens under electron microscopes

- Photographic negatives

- Micro miniature assemblies

- Electromechanical instruments

- Magnetic tapes & heads

- Servomechanisms

- Computer peripherals

- The Cobra Duster extension, MS-228, may be used in conjunction with the AeroDuster® for delivery to elusive trouble spots on various equipment.

Physical Properties of a HFC 134a Duster Spray Propellant

| Molecular Weight | 102.03 |

| Boiling Point | -15.0°F/-26.1°C |

| Vapor Pressure (mmHg) | 96.5 psia @ 77°F/25°C |

| Density | 1.21 @ 77°F/25°C |

| VOC | Exempt |

| ODP | 0 |

Ultra-Low Global Warming Potential – Alternative to MS-222N Duster Spray

An excellent alternative to the AeroDuster® MS-222N Duster Spray is MS-222L AeroDuster®. A low global warming formulation, which meets the low gas requirements of EPA. With with no traces of contaminates and oils, MS-222L is the supeior choice for critical electronics applications. Removes microscopic dust and is ideally recommended for electro-mechanical instruments, computer equipment, optics and other equipment. Low GWP (global warming potential). No ODC (ozone depleting chemicals).

60+ Plus Years of Experience in the Composite/Electronic Industry – at your service.

At Miller-Stephenson, we not only understand the challenges that electronic and composite manufactures face, we also recognize the diversity of raw materials utilized in the process. Although these processes are always changing, our MS-222N AeroDuster® Duster Spray, MS-242, and additional series of high-performance aersols, safety and easy of use. Our complete line of freeze and blowing agents provide manufacturers with non-flammable, VOC-compliant products with new products offers ultra-low global warming content. Miller-Stephenson prides itself on providing distinctive, robust, formulated products, developed to serve your requirements and positively affect the efficiency of your process, the quality of your products and your operational costs. For any further technical service questions or concerns please contact our technical support team. For Technical Assistance please click here.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

- Evaporates quickly

- Leaves no residue

- Safe for most plastics, elastomers and metals

- Noncorrosive

- Low toxicity, compared to alternative solvents

- Non ozone depleting

- RoHS Compliant

| Boiling Point | 82°C |

| Liquid Density | 0.79 g/ml |

| Vapor Pressure | 33 mmHg |

| Percent Volatile | 100% |

| Water Content | <0.10% |

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

- Semiconductor chips

- Specimens under electron microscopes

- Photographic negatives

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.

MS-222N (14 oz Aerosol)

MS-222T (10 oz Aerosol)

MS-222L (10 oz Aerosol) (Low Global Warming)

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.