No products in the cart.

Aerosol Freeze Spray | MS-242L Quik-Freeze® Ultra

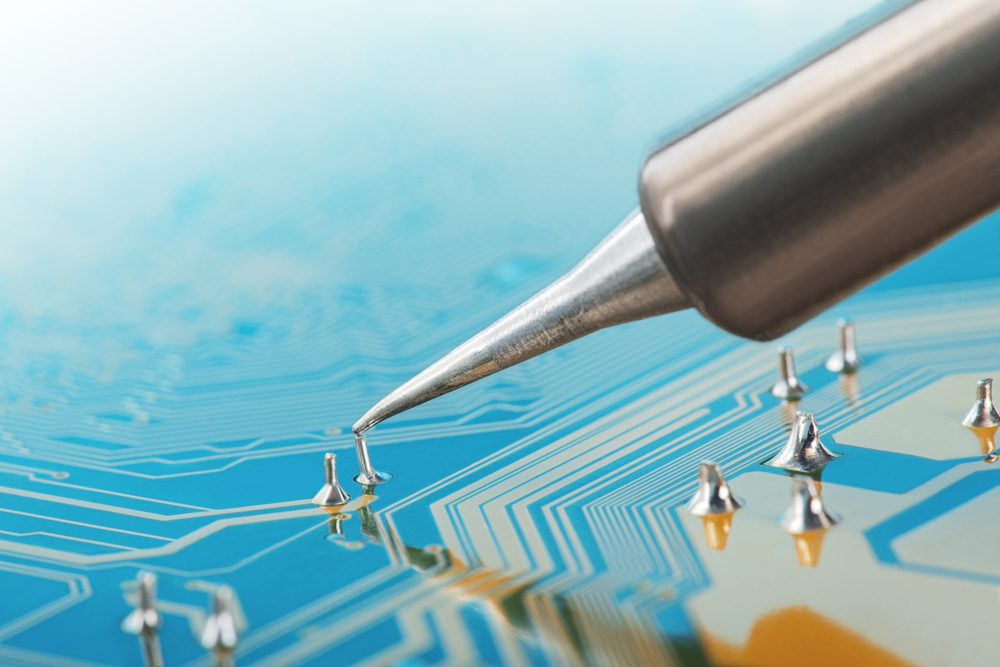

MS-242L Quik-Freeze® Ultra is a Low Global Warming version of MS-242N. Used for hot-cold intermittence testing of electronic components and protection of components during soldering. Excellent for cooling of epoxy-composite forming and freezing biological specimens. Instantly freezes small areas to -54ºF(-47ºC) with No ODC (ozone depleting chemicals). Benefits of this product include:

- Ultra Low Global Warming, VOC Exempt, Nonflammable

- Instant target freeze potential

- Protects components from solder

- Compatible with most plastics, rubbers and metals

CLICK HERE TO CHAT WITH AN EXPERT ABOUT THIS PRODUCT