Krytox™ Lubricant Articles

Industrial Lubricants That Can Reduce Production Downtime

Comparing Industrial Lubricants – Downsides of Hydrocarbons

Petroleum-Based and Synthetic Hydrocarbon Lubricants vs. Krytox (PFPEs)

While industrial lubricants only make up 1% of plant operational costs, the lack of proper lubrication or application can have an adverse impact on total maintenance costs and downtime. More than half of the total maintenance costs, as well as a cause of downtime, is directly related to one of the smallest budgeted items.

The ultimate industrial lubricant is one that lasts a long time and “just works.” That means it works just as well under normal temperature conditions, as well as in an extremely hot environment; or when faced with harsh chemicals, like boiling sulfuric acid.

One class of non-traditional synthetic industrial lubricants – perfluoropolyether (PFPE) lubricants – provides longerlasting performance, which results in reduced wear and tear for machine parts, lower maintenance costs and fewer production delays, even in the harshest environments.

Parts and equipment generally require more maintenance and capital reinvestment in environments where extreme temperatures and pressures are combined with harsh chemicals and conditions. Traditionally used petroleumbased hydrocarbon lubricants break down and fail at extreme temperatures with pressure and chemical exposures, requiring more frequent machine maintenance and causing shorter parts lifespans. Traditional synthetic industrial lubricants may provide only marginally better results.

PFPE lubricants are proven to provide the broadest benefits, even in the most extreme conditions without breaking down. Using PFPE reduces equipment failure, maintenance cost, parts replacement and labor costs. More importantly, it reduces production downtime.

Though more expensive than petroleum-based and other traditional synthetic industrial lubricants, PFPEs provide a short payback period and long-term benefits.

Stable Performance in Harsh Environments

One of the greatest advantages of using PFPE lubricants is stability across a wide variety of operating conditions and environments. This inert nature is what allows PFPE greases and oils to outlast and outperform competing traditional synthetic and hydrocarbon products.

In addition to PFPE lubricants being chemically inert compared to virtually all chemicals commonly used in most industries, they are also water and oil repellent, solvent resistant, nonflammable, compatible with oxygen and reactive gases and non-toxic. And, they are compatible with most common elastomers, plastics and metals.

Even with PFPEs having such extreme capabilities, they are completely safe to handle. When comparing the MSDS of Krytox™ lubricant, a type of PFPE lubricant, to the MSDS of sugar, sugar is more dangerous to handle.

Using PFPE lubricants can contribute significantly to lowering the cost of doing business – industries, such as aerospace, automotive and chemical, have used PFPEs with exceptional performance and reliability in the toughest conditions, where productivity matters and downtime is costly.

Extreme Compatibility

PFPE lubricants are stable and effective among other lubricants as well as steam, moisture and harsh chemicals. Because of their chemically inert properties, PFPE lubricants are safe to use with more than 100 different chemicals without degradation, including boiling sulfuric acid.

Can Your Industrial Lubricant Stand t he Heat?

he Heat?

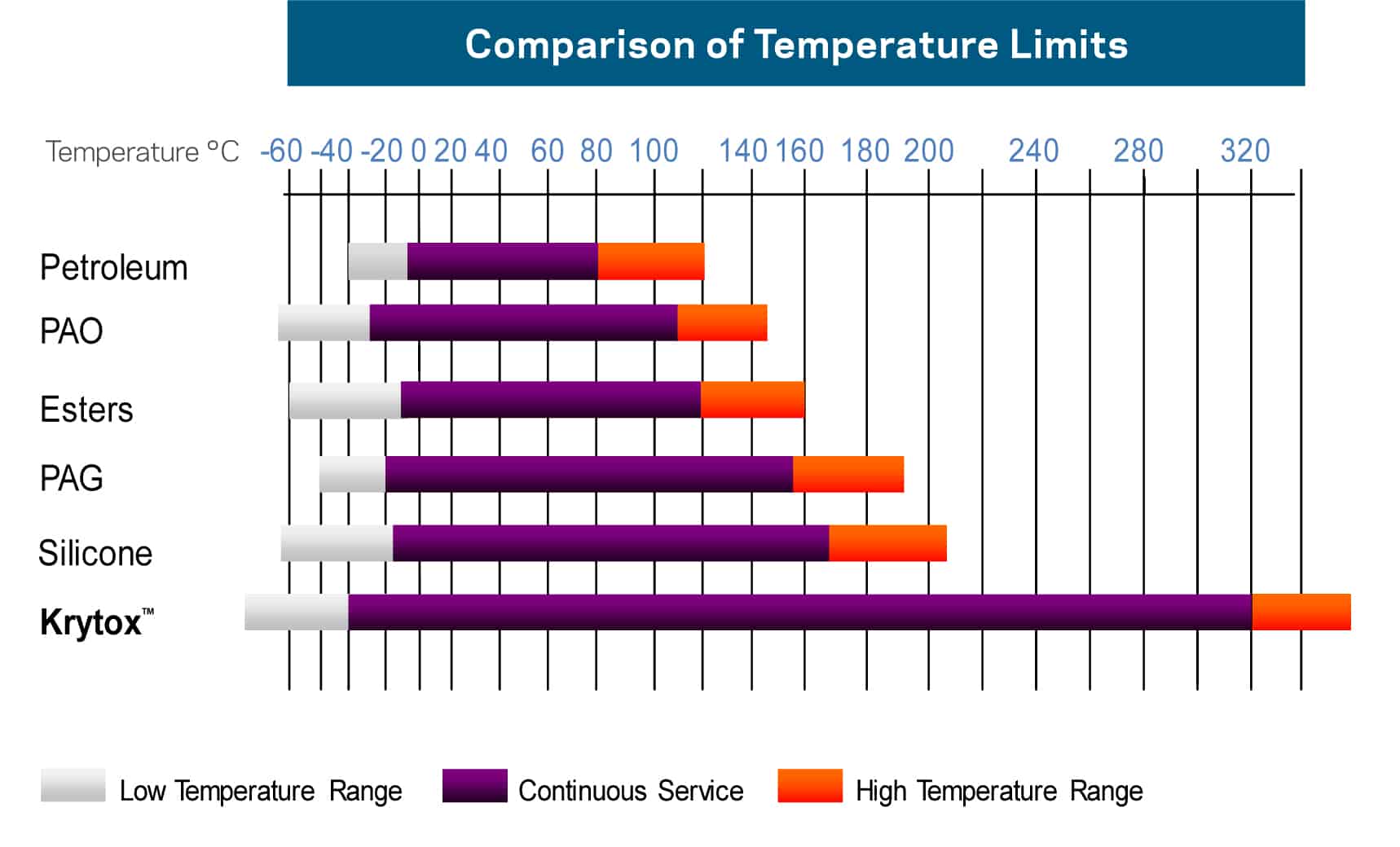

As machine operating temperatures rise above 120 °C or fall below 0 °C, petroleum-based lubricants begin to fail, forcing costly re-lubrication and production interruption. Conventional synthetic lubricants (esters, polyalkylene glycols and polyalphaolefins) don’t perform much better. Krytox™ PFPE industrial lubricants are stable up to 350 °C and down to – 75 °C.

Extreme Temperature Side by Side

In a side-by-side high temperature test, hydrocarbon and PFPE (Krytox™ GPL 227) grease were placed in an oven at 232 °C (450 °F) for 40 hours. The hydrocarbon grease lost 40 percent of its weight (ceasing to be an effective lubricant), and developed tar. Krytox™, the PFPE grease, remained unchanged in weight and appearance (lubricating ability fully intact).

Extreme Pressure (EP)

PFPE greases with extreme pressure additives have high load-carrying capability and good lubrication characteristics under boundary and mixed friction conditions, making them ideal for use in high loading and slow speed conditions. In addition, PFPE oils provide inherent extreme pressure performance based on their unique chemistry.

Several tests have proven that PFPEs outperform and outlast hydrocarbon lubricants

In a Pin and Vee Block Test (ASTM D-3233) – an evaluation of wear, friction and extreme pressure – Krytox™ (PFPE) lubricants reached the maximum load in the test, while hydrocarbon lubricants displayed signs of extreme wear and often caused a catastrophic early failure.

PFPE lubricants again outperformed hydrocarbon lubricants in a four ball extreme pressure test (ASTM D-2596), which measures a lubricant’s performance under extreme pressure using a point contact sliding motion. Petroleum greases have a load wear index (LWI) of approximately 50, and synthetic hydrocarbons have LWIs close to 100. PFPEs were stable at LWIs more than twice the LWIs of hydrocarbon lubricants and matching or exceeding the LWIs of synthetic hydrocarbons.

Another test steadily increases the load on a rotating steel ball in contact with 3 fixed balls until they seize and welding occurs, which simulates point contact conditions. The lowest load (Weld Point) data is used to calculate the value of how well the grease prevents wear when operating below the weld point. For many competing greases, the LWI can generally fall between 50 and 100, but Krytox™ greases typically have an LWI well above 100, further illustrating how Krytox™ grease can outperform most competitive greases in both extreme pressure and extreme condition performance.

The Test of Time

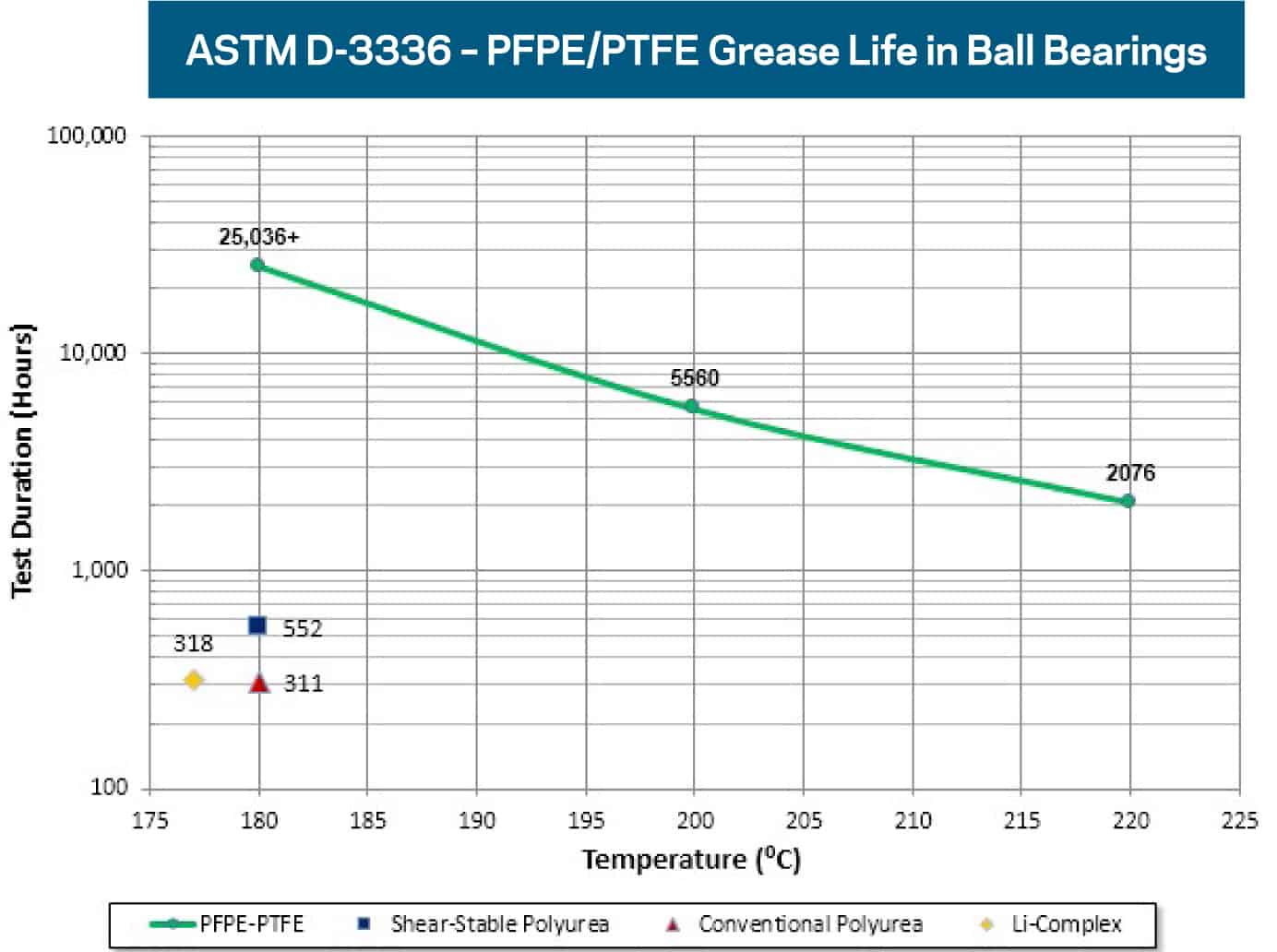

PFPEs outlasted hydrocarbons in the ASTM D-3336 test, which evaluates the endurance life of greases in ball bearings by rotating a bearing at a set speed and temperature. At 10,000 revolutions per minute (rpm) and about 177 °C (350°F), all tested hydrocarbon lubricants failed in less than 1,000 hours. Krytox™ AUT 2E45 grease performed for more than 25,000 hours – the equivalent of almost three years – without failing. The test was stopped before the lubricant failed.

Case Study: Copper Rod Manufacturer’s Experience

Before using PFPEs, a copper rod manufacturer believed lubricating its rollers’ bearings (operating temperatures over 200 °C [400 °F]) every four hours with a synthetic hydrocarbon grease was the longest lasting solution available. By switching to a PFPE lubricant (Krytox™ XHT-BDX lubricant), they lowered re-lubrication to a monthly basis and cut annual bearing failures by nearly 98% (reducing replacements from 186 bearings each year to four). By switching to PFPEs, this copper rod manufacturer reduced maintenance costs, parts costs and production downtime.

The Choice is Clear with Krytox Industrial Lubricants

Traditionally, PFPEs have been only considered for applications running in extreme conditions. Today, more customers are realizing the benefits of PFPE lubrication in the more mundane applications where they had never been considered before. Krytox™ lubricants, a type of PFPE, provides exceptional value in use across a wide range of applications.

High performing PFPE lubricants cost more per unit than hydrocarbon lubricants; however, the exceptional benefits of PFPE outweigh the costs: PFPEs cut maintenance costs, reduce part replacement costs and help reclaim lost opportunity.

Estimate Whether You Should Switch to PFPEs

- Calculate Staff Opportunity Cost

Estimate the time your company spends on maintaining lubricated parts. (What if the personnel were assigned elsewhere in the plant, if they did not have to do re-lubrication?) - Estimate All the Maintenance Costs

Add up all the costs of re-lubricating equipment, e.g., electric motors, including the cost of staff time, lubrication supplies and part replacement. - Add Up the Opportunity Costs

Estimate the amount of downtime caused by re-lubrication and unscheduled lubrication due to equipment failures. Then, estimate the value of the product your company could have produced. Multiply the product sales volume by your product gross margin amount. - Contact a PFPE Manufacturer or Supplier

For example, Miller-Stephenson, which distributes Krytox™ lubricants, to calculate the savings available by switching to PFPE lubricants.

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.