Polyurethane Conformal Coating | ShieldSys™ 470X | MIL-SPEC

$25.47

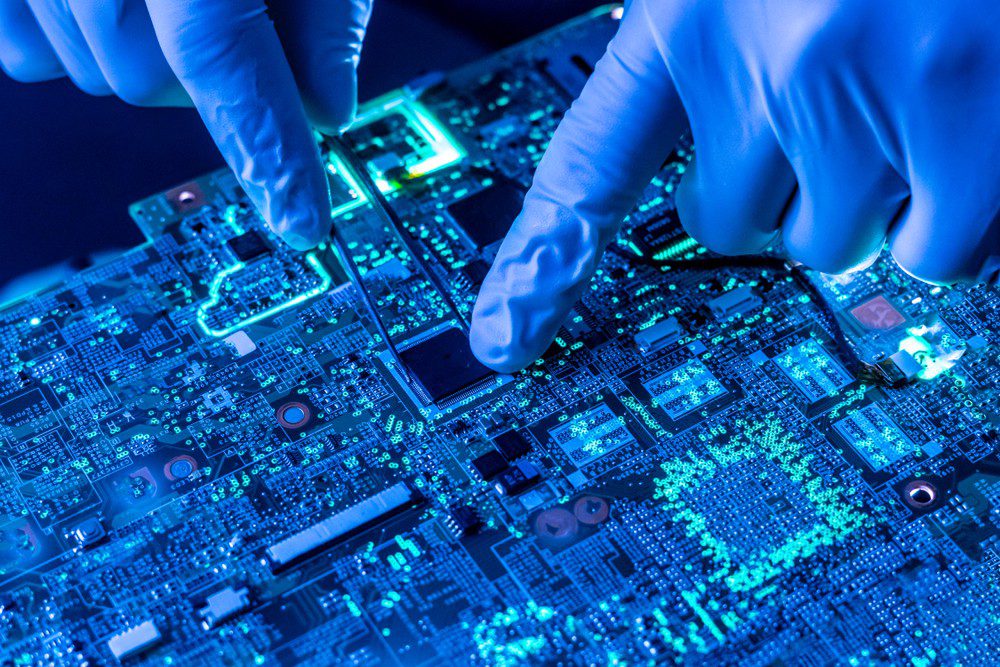

ShieldSys™ 470X Polyurethane Conformal Coating is Miller-Stephenson’s most advanced conformal coating, utilizing our exclusive high-density crosslinking polyurethane resin. This single-component, pre-catalyzed coating offers ease of application, and self-leveling properties ensuring the coating wets all areas of the board and cures to a smooth profile with predictable film thickness.

- Exclusive High-Density Polyurethane Conformal Coating

- Superior Toughness and Abrasion Resistance

- Solvent, Humidity, and Corrosion Resistant

- Base resin meets MIL-I-46058C Type UR

- IPC-CC-830 qualified and UL94 V-0

Polyurethane Conformal Coating | ShieldSys™ 470X

High Performance Crosslinking Urethane Resin; Superior Adhesion and Chemical Resistance; MIL-I-46058C Approved

ShieldSys™ 470X Polyurethane Conformal Coating is our next generation urethane conformal coating optimized for aerosol spray application. ShieldSys™ 470X is ideal for coating circuit assemblies, touch up, and repair work. The easy to use and excellent flow out characteristics ensures even, uniform coverage. The advanced polyurethane conformal coating applied by the ShieldSys™ 470X delivers a tough, durable protective film with excellent electrical and barrier properties. The single-component coating offers ease of application and the self-leveling properties ensure the coating wets all areas of the board and cures to a smooth profile with predictable film thickness. The robustness of the ShieldSys™ 470X Polyurethane Conformal Coating provides a cured film exhibiting superior humidity, abrasion, and chemical resistance and will maintain its properties even after long exposure to the elements with minimal color change.

Benefits of ShieldSys™ 470X Polyurethane Conformal Coating

- Exclusive High Density Polyurethane Conformal Coating

- Easy to use and Reliable Aerosol Spray

- Superior Toughness and Abrasion Resistance

- Excellent Solvent, humidity, and corrosion resistant

- Reworkable and Room Temperature Cure

- Exceptional Dielectric Properties

- Base resin meets MIL-I-46058C for Type UR

- IPC-CC-830 qualified and UL94 V-0

Applications of ShieldSys™ 470X Conformal Coating

ShieldSys™ 470X Polyurethane Conformal Coating finds typical applications where moisture, aggressive chemicals/vapors, large temperature variations, vibrations, or fungal exposure may be present. Fully cured, our coating offers excellent resistance and protection to PCBs ensuring long term reliability and consistent performance in the field. Our superior chemistry can be found in applications requiring unmatched reliability such as defense, automotive, and aerospace applications. Furthermore, the base polyurethane conformal coating resin meets MIL-I-46058C making it ideal for new or repair work on sensitive control boards.

- Touch-up and repair work

- Large temperature fluctuations or humid environments

- Protection from aggressive solvents or vapors

ShieldSys™ 470X Polyurethane Conformal Coating: Advanced Chemistry, Superior Performance, Reliable Application – A Potent Combination

ShieldSys™ 470X was developed from inception to be the most advanced, reliable, and convenient polyurethane conformal coating available. The combination of exclusively Miller-Stephenson high-density crosslinking resin technology and our utilization of advanced wetting/leveling agents, the ShieldSys™ 470X generates consistent, uniform thin films on PCB and components regardless of application method. This very forgiving coating offers superior chemical and mechanical properties while exhibiting a room-temperature cure and the ability to be reworked.

Polyurethane Conformal Coating | ShieldSys™ 470X Electrical & Physical Properties:

Cure Electrical Properties

| Dielectric Strength, volts/mil | 3500 |

| Dielectric Constant @ 10^5 Hz | 2.7 |

| Dissipation Factor @ 10^5 Hz | 0.020 |

| Volume Resistivity (ohm) | 1.5 x 10^15 |

Cured Physical Properties

| Operating Temperature: | -67 °F/-55 °C to 230 °F/ 110 °C |

| Appearance: | No blistering, wrinkling, cracking, or peeling of film, after thermal shock and moisture resistance testing. |

| Flexibility: | No cracking of film over a 1/8″ diameter mandrel. |

| Fungus Resistance: | Non-nutrient per ASTM G21 |

| Fluorescent: | Under ultraviolet light. |

50 years of experience in the Electronics Industry – At Your Service!

Miller-Stephenson has been manufacturing and formulating polyurethane conformal coating for over 50 years. We have the technical and application expertise to help your team choose, apply, and rework any conformal coating within our portfolio. We offer both commercial and MIL-spec coatings, and all of our coatings are held to the highest performance standards. When choosing any of our conformal coatings you can expect the following benefits:

- Simple, reliable application process

- Specialized formulas to provide uniform, thin films

- Easy removal, repair, and replacement

- Superior Protection against thermal and mechanical shock

- MIL-Spec and Commercial-Spec polymer coatings

Notwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.