Krytox™ Lubricant Articles

Krytox™ Frequently Asked Questions (FAQ)

Krytox FAQ

Introduction to Krytox Lubricants

What is Krytox FAQ?

Krytox is the Chemours brand name for a range of clean, specialty synthetic lubricating materials available in numerous grades for a wide range of applications. Krytox lubricants have become the product of choice where extremely high or low temperature performance, nonflammability, oxygen compatibility, and resistance to aggressive chemicals are required. In this Krytox FAQ we discuss all the uses, applications and specifications of Krytox.

What are the primary differences in Krytox oils?

- Krytox XHT oils have additional treatment to make them more thermally stable at temperatures over 300 °C (572 °F) and have very high viscosity to withstand the temperatures and provide adequate lubrication.

- Krytox aerospace oils have more strict volatility specifications and are a narrower distillation than GPL oils.

- Krytox vacuum pump fluids are distilled to give an excellent vapor pressure and are designed for specific OEM pumps.

- Krytox linear oils have a better viscosity index and operate over a wider temperature range.

- Krytox GPL oils are formulated to provide a cost effective base oil for industrial applications.

Does Krytox contain silicone?

No. Krytox oils and greases do not contain any silicones,and there are no silicones used in processing.

What are the different grades of Krytox GPL lubricants and their typical applications?

- The Krytox GPL 10X oil /20X grease series contain no additives and can be used on components that come in contact with most chemicals typically used in industry. Typical applications include valves or bearings, seal barrier fluids, instruments, and oxygen systems.

- The Krytox GPL 21X series contains molybdenum disulfide for extreme pressure (EP) conditions and should be used for slow speed or extremely heavily loaded applications.

- The Krytox GPL 22X series contains sodium nitrite corrosion/anti-wear inhibitor; it also improves load carrying performance and is ideal for corrosive environments. Typical applications are automotive bearings, sealed pump bearings, electric motor bearings, and general-purpose bearings.

- The Krytox GPL 29X greases have EP and anticorrosion additives, and have been formulated for applications that need both high load carrying capacity and anti-corrosion protection.

- The Krytox GPL 2EX lubricants are formulated using new anti-rust additives. This grease is similar to the GPL 22X series greases, but contains a non-nitrite anti-corrosion additive.

What is Krytox made of?

Krytox fluorinated oils are a series of low molecular weight, fluorine end-capped, homopolymers of hexafluoropropylene epoxide. The polymer chain is completely saturated and contains only the elements carbon, oxygen, and fluorine; hydrogen is not present. On a weight basis, typical Krytox oil contains 21.6% carbon, 9.4% oxygen, and 69.0% fluorine.

Krytox FAQ Applications

Where can Krytox lubricants be used?

Krytox lubricants can be used in applications where nonflammability, oxygen compatibility, materials compatibility, high temperature stability, and resistance to aggressive chemicals are requirements. Some examples include:

- Automotive: Wheel bearing grease, CV joint grease, universal joint grease, fan clutch bearing grease, emission air pump grease, spark plug boot lubricant, weather stripping lubricant, sunroof seal lubricant, clutch throw out bearing grease, ABS system grease, paint plant conveyor bearings, paint spray system valve lubrication, gasoline pump bearings, windshield wiper motors, oil pressure sensors, truck window lift mechanism, sintered bearings in motors, leather seats, consoles and trim, flocked and unflocked window seals and channels, door handles, switches, air vents, controls

- Aviation: Fuel resistant grease, oxygen compatible grease, ventilation fan bearing grease, cruise missile rear main bearing lubricant, starter bearing grease, emergency generator bearing grease, missile launch

platform gear lubricant, space shuttle lubricant, sealant - Pumps: Vacuum pump fluid for corrosive and hazardous service, bearing grease for chemical pumps, O-ring lubricant, barrier fluid between double mechanical seals • Industrial: Corrugator and paper machine bearings, aluminum can manufacturing bearings, vacuum sputtering machines, welding machines, gear oil, linear bearing lubricant, high temperature fans, clean rooms, chlorine service, textile equipment, tenter frames, high speed motors, instrument bearings, sealed-for-life motors, conveyor system in glass and aluminum plants, textile calender roll bearings, brick kiln car bearings, film blowing machines

- Nuclear: Submerged sump pump bearings, containment cooling fans, snubbers, control rod drive mechanism fan motors

- Valves: Lubricant for valve stem packing, relief valve lubricant, O-ring lubricant, steam turbine control valves, low emissions valve stem packing lubricant

- Miscellaneous: Anti-seize lubricant, bolt thread lubricant, water purifier lubricant, self-contained breathing apparatus lubricant, cryogenic lubricant, vacuum system sealant, drive chains, hydraulic fluids, instrument barrier fluids, heat transfer fluids, geothermal system grease, mold release agent, fishing reel grease, industrial toast making oven conveyor bearings, windmill gearboxes, glove curing conveyor

What is the NLGI consistency of Krytox grease grades?

Greases are formed by mixing the base oil with a thickener to form a grease. Krytox greases use a special high-thickening efficiency, low molecular weight polytetrafluoroethylene (PTFE) with very small particle sizes as their thickener. This is one of the most thermally stable thickeners for high-temperature, long-term greases. The higher thickening efficiency of the special PTFE thickener allows Chemours to formulate grease to

maximize oil content for improved grease performance.

Greases can be formulated with different viscosity oils to handle different temperatures and load conditions. High viscosity oils can be used in greases for high temperatures, heavy loads, or low speed applications.

Low viscosity oils can be used in greases where low temperature properties are important or speeds are higher. Lower amounts of thickener form softer or more fluid-like greases. Higher solid levels form harder, stiffer

greases. Additives are often added to the grease to enhance anti-corrosion protection, raise load carrying ability, or help reduce wear.

Our standard grease grade is NLGI Grade 2; however, upon request, we produce NLGI Grades 000 through 6.

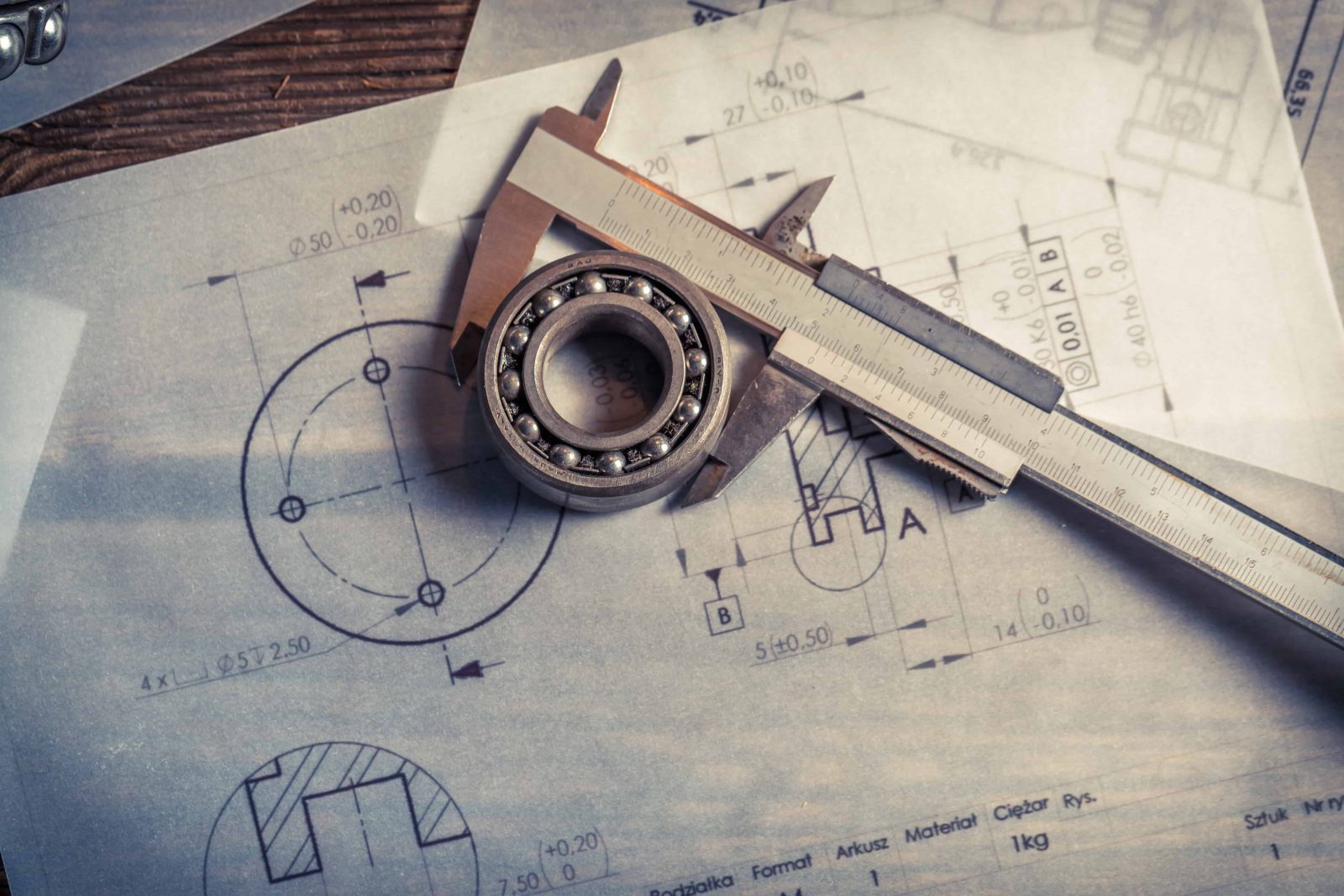

Do I need to do anything special before using Krytox in bearings?

Before adding Krytox grease to a bearing, the bearing should be cleaned of all existing greases, oils, or preservative oils used during storage. If hydrocarbon oils are left in a bearing, the oils can form carbon deposits at high temperatures that may accelerate bearing failure. Please ask for “New Bearing Preparation with Krytox Lubricants” for the recommended cleaning and repacking procedure, as well as guidance on how much grease to use and speed considerations.

Is ongoing lubrication required once we’ve begun using Krytox?

Re-lubrication of bearings may be required: typically every 1–3 months for corrugators, depending on the equipment operating temperature. For other applications, re-lubrication intervals can be from months to years or

potentially never in the case of sealed systems.

Can I mix Krytox grease with other greases?

The performance benefits of Krytox grease will not be achieved if Krytox is mixed with a non-perfluoropolyether (PFPE) grease. The performance of the grease mixture will be limited by the properties of the non-PFPE grease in the mixture. Krytox grease will not react with the other grease, nor cause decomposition or any hazardous reactions. The mixing tests that Chemours has done have shown that the mixture sometimes softens up by about one penetration grade when it is heated up. This normally will not be enough change to cause any significant problems.

The Krytox grease will not stop the other lubricant from breaking down from heat and oxidation. It is likely that the additives in the hydrocarbon grease have coated the bearing surfaces, and the Krytox grease will not be able to adhere to the bearing—so most of it might get thrown out of the bearing.

Characteristics of Krytox FAQ

What approvals and certifications do Krytox lubricants have?

Krytox lubricants have the following certifications:

- ISO 9001 Certified Quality Management System

- ISO 14001 Certified Environmental Management System

In addition, certain grades have the following approvals:

- MIL-Spec PRF-27617 approved grades for aerospace and aviation use

- NSF H-1 food grade lubricants approved for incidental food contact

- Independently tested and confirmed for LOX and GOX use by major oxygen manufacturers and certification authorities

Are Krytox lubricants flammable?

No. Krytox lubricants are not combustible, nor do they ignite.

How stable is Krytox when exposed to chemicals?

Krytox PFPE oils and greases thickened with PTFE exhibit exceptional chemical stability. Krytox oils and greases will not react with most chemicals (with the exception of Lewis acids and alkali metals) and other

lubricants, nor cause them to degrade. Krytox performance lubricants are not only resistant to oxygen and reactive gases, but they are inert to virtually all chemicals commonly used in most industries. For further information, please ask for “Krytox Lubricants: Chemical Stability.”

Is Krytox compatible with nonmetallic materials?

Yes. Krytox oils and greases have been used as plastic or elastomer component lubricants for over 40 years. For more specific information, please ask for “Krytox Lubricants Plastics and Elastomer Compatibility.”

Is Krytox oil hard to clean up?

The very characteristic that makes Krytox lubricant work as well as it does, i.e., its inertness to chemical attack, also makes it insoluble in most common solvents and is why it cannot be washed out with water. A small amount of a fluorinated solvent such as Krytox Solvent, Krytox HC Plus Cleaner, or Vertrel XF on a rag or towel will easily remove remaining traces of Krytox. For additional information, please request “Krytox HC Plus Cleaner” and “Krytox Solvent.”

What is the shelf life of Krytox lubricants?

Krytox greases and oils with no additives have an indefinite shelf life if left unopened and stored in a clean, dry location. The service life of Krytox is difficult to predict because there are so many variables. Testing

documents Krytox grease at 200 ºC (392 °F) and 10,000 rpm for over 5,000 hours in an ASTM D3336 life test, and the bearings did not fail. For more detailed information, please ask for “Shelf Life Profile of Krytox

Lubricants.”

What lubrication equipment can I use with Krytox grease?

Generally, any lubrication equipment manufacturer’s gun or pump that fits a standard grease cartridge or grease bucket should work. For more information about equipment grades and a discussion of grease fittings,

please ask for “Equipment Selection for Applying Krytox Lubricants.”

TO BROWSE OUR KRYTOX CATALOG, SELECT A CATEGORY BELOW:

This Krytox FAQ is for educational purposes. To find your appropriate grade of Krytox please contact us or click here to visit our Krytox database.

Krytox™ is a trademark of The Chemours Company FC, LLC.

The recommendation made here with and the information set forth with respect to the performance or use of our products are believed, but not warranted to be accurate. The products discussed are sold without warranty, as to fitness or performance, express or implied and upon condition that purchasers shall make their own test to determine suitability of such products for their particular purposes. Likewise, statements concerning the possible uses of our products are not intended as recommendations to use our products in the infringement of any patent.