No products in the cart.

Products

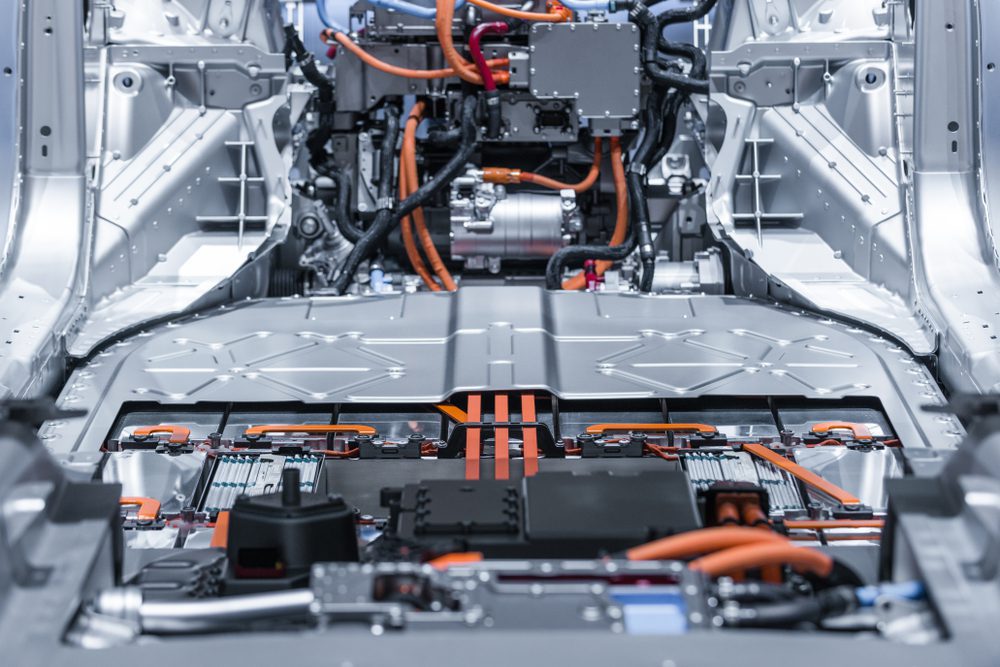

Chemours’ Krytox™ expanded its high-performance lubricant line in 1981 to handle the demands of the automotive industry and offer superior lubricants to hydrocarbon-based alternatives. Specialty automotive formulations of Krytox™ lubricants provide superior performance and durability characteristics including significantly reducing re-lubrication intervals and 98% reduction in bearing failure. These low volatility lubricants include high penetration oils and ultra-low to zero motility greases, some of which are H1 certified. Chemours’ strict manufacturing regulations and optimization of their fluorochemicals exhibit a predictable viscosity index and longevity performance characteristics at a wide temperature and pressure range, which is crucial to all automotive applications. Miller-Stephenson is a direct channel partner with The Chemours Company for the North American distribution of Krytox and provide world-class technical support, assistance, and reliable customer service.

AUT Series

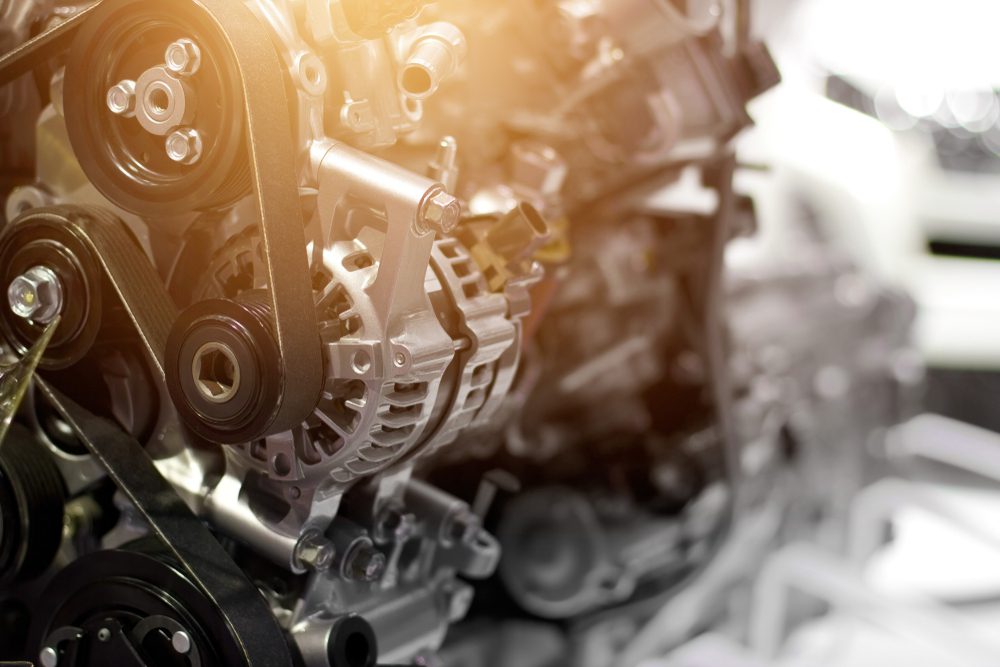

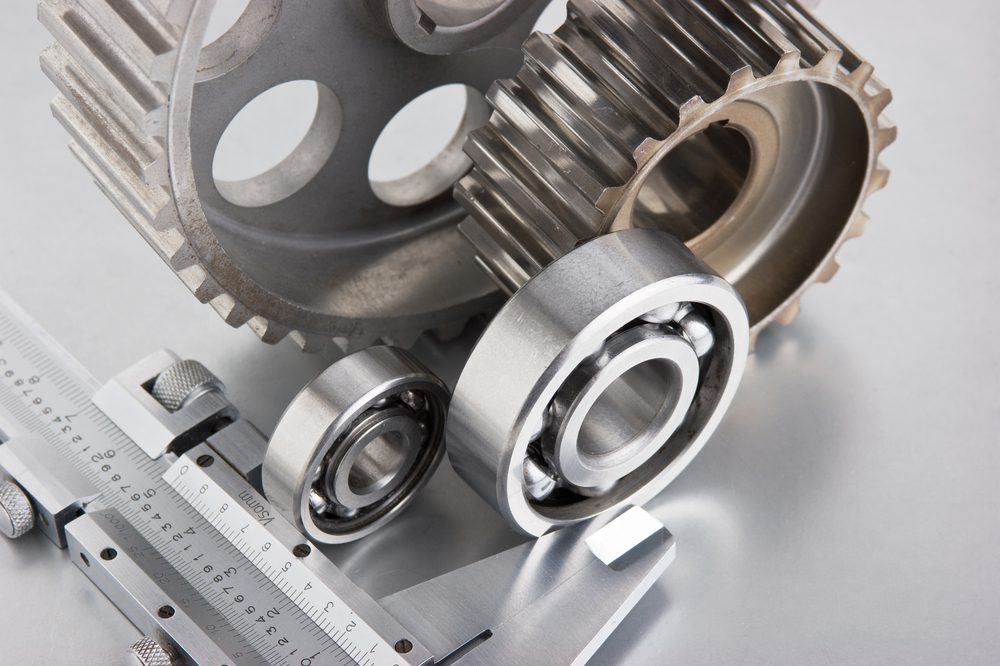

Krytox™ AUT series are long lasting greases that are specifically formulated for the automotive industry, offering superior chemical and thermal stability. Provides flexible options for anti-corrosion and water washout protection with proprietary additives.

AUT 2045: Elimination of spark plug boot-adhesion and boot cracking.

AUT 2E45: Formulated with a sodium nitrite free anti-rust additive for applications such as O rings and ball and bench bearings.

AUT 2245: Utilizes sodium nitrite as an anti-corrosion additive for applications such as fan clutch bearings and alternator rear bearings.

GPL 100 Series

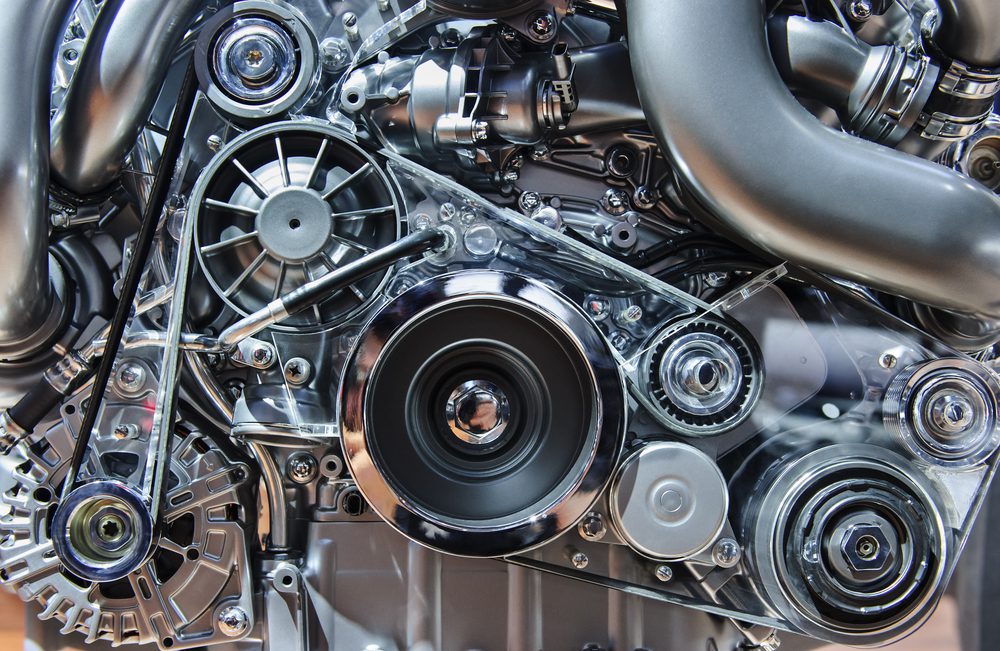

Krytox™ GPL 100 series are highly regarded for their NVH (Noise, Vibration, and Harshness) and weather stripping properties, especially for interior automotive parts, bushings in the windshield wiper motor, elimination of stick-slip, and electronic parking brake mechanisms. These high penetration PFPE oils act as the base oil for the entire GPL grease series. Also, are utilized for their stability in a wide variety of operating conditions and environments. GPL oils are durable and therefore extremely long lasting lubricants that offer broad material compatibility.

GPL-100 series TDS Quote

GPL 200 Series

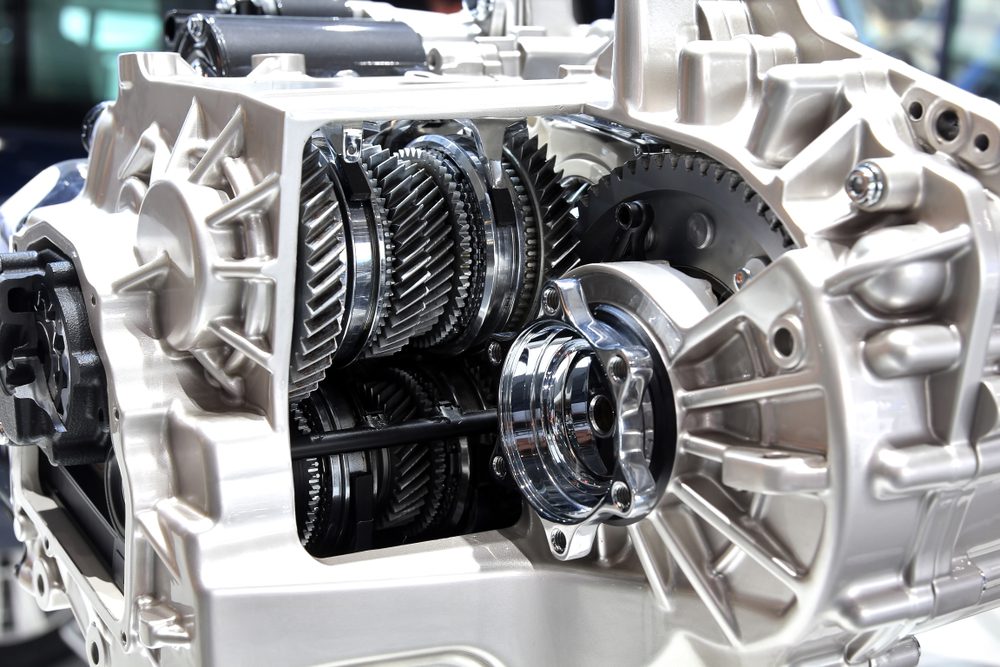

Krytox™ GPL 200 series are additive-free fluoropolymer greases that are utilized extensively throughout the automotive industry. Offers broad material compatibility, high temperature stability, and significantly reduced maintenance costs. NVH squeak and rattle elimination, O ring, and assembly line lubrication are just a few proven applications.

GPL 204: Provides elimination of spark plug boot-adhesion and boot cracking. Lubricates plastic gears and exterior rearview mirrors.

GPL 205: Lubricates hydraulic clutch actuators, elastomeric seals.

GPL 207: Resistant to coolant wash-off. Superior grease for the actuator rod in the cooling system thermostat.

GPL 210 Series

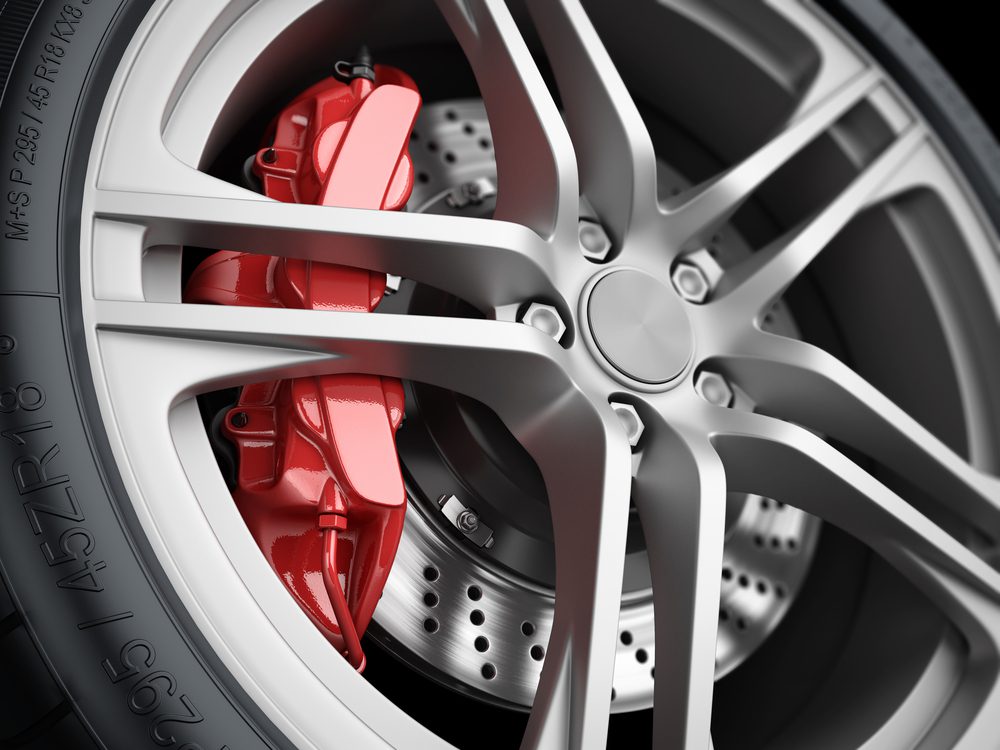

Krytox™ GPL 210 series utilizes molybdenum disulfide as a high pressure additive. The addition of this additive results in exceptional performance for a broad temperature and pressure range to which some automotive parts are exposed. These high quality, heavy-duty black greases are used for high loading or slow speeds and are effective for squeak and rattle elimination. Applications include CV joints, splined shafts, steering rack, and U-joints.

GPL-210 Series TDS Quote

GPL 220 Series

Krytox™ GPL 220 series has a superior anti-corrosion/anti-wear inhibitor, sodium nitrite. These greases are utilized for rust protection at ambient temperatures and corrosion protection at high temperatures. Properties like resistance to under-hood contaminants, high temperature stability, and durability make it ideal to lubricate and protect moving parts susceptible to oxidation.

GPL 225: Typical applications are automotive bearings subject to oxidation, fan clutch, alternator rear bearings, turbo and superchargers.

GPL-220 Series TDS Quote

GPL 295

Krytox™ GPL 295 offers extreme pressure, anti-wear, and anti-corrosion additives. Delivers exceptional performance in areas that are exposed to both high pressure and oxidizers. Provides an effective fretting corrosion resistance, along with high temperature stability to ensure very long life in these otherwise vulnerable applications. Ideal for lubrication of clutch pilot bearings.

GPL 295 TDS Quote

GPL 255

Krytox™ GPL 255 utilizes low levels of fluorescing agents to allow the grease’s appearance to change under an ultraviolet lamp or “black light”. The naturally white grease appears a yellowish-green color once it is exposed to UV light. This allows the grease to be hidden on a white surface under normal circumstances, but easily visible during manufacturing processes. GPL 255 can also allow confirmation that the grease did not migrate. GPL 255 grease is also available in the oil form as the GPL 155.

GPL 255 TDS Quote

XP Series

Krytox™ XP series is formulated using patented soluble additives that will not wash away or be left behind with the grease thickener. Provides anti-corrosion, anti-fretting, and high temperature stability properties, as well as resistance to separation under centrifugal loads and to diesel exhaust fumes. Perfect choice for bearings in truck automatic clutches to decrease noise and extend the life of the part. Other proven applications include lubricating actuator gears in EGR valves and bearings.

XP Series QuoteSpecialty Solvents

Miller-Stephenson offers ultra-high purity specialty solvents designed for a wide range of critical cleaning and degreasing applications due its exceptional material compatibility. The removal of residual particles and contaminants is crucial as they may hinder, cause failure, or ignite. Vertrel™ and Opteon™ specialty cleaning solvents are highly regarded for their ability to clean Krytox and other fluorinated lubricants, machine oils, PCBs, and electronic components from a multitude of automotive parts due to their exceptional compatibility with most plastics, elastomers, and metals. Ideal replacements to nPB and TCE due to their safety profile, high solvency power (Kb values), fast evaporation/dry times, material compatibility and non-flammability.

Vertrel™ Series

Vertrel™ specialty fluids are heavily utilized in the automotive industry because of their exceptional cleaning performance across a broad range of soils such as oils, greases, waxes, and hydraulic fluids with the added benefit of non-flammability and greater work safety. Thanks to their high penetrations and low surface tensions, Vertrel solvents are able to clean tight areas and provide superior cleaning performance versus hydrocarbon and water-based cleaners. Their fast-drying property also allows for an increase in productivity due to less downtime. Vertrel solvents are effective at removing Krytox lubricants and machine oils from a multitude of automotive parts due to their exceptional material compatibility.

Vertrel™ Series Quote

Opteon™ Series

Opteon™ solvents are ideal for the removal of greases, oils and other particulates on a multitude of automotive parts during precision and cold cleaning due to their high Kb values (solvency power), penetration and material compatibility. Superior fluids for critical cleaning and vapor degreasing applications because of their low surface tension, low boiling point, and non-flammability properties. In addition, these specialty solvents have an ultra-low global warming potential and are 100% non-ozone depleting and therefore are eco-friendly. Combining their safety profile for both humans and the environment with their superior cleaning performance, these solvents are much more efficient than water and hydrocarbon based alternatives.

Opteon™ Series QuoteRelease Systems/Dry Films

Many of Miller-Stephenson’s dry film/release systems utilize proprietary fluoropolymer or siloxane resins to provide optimal lubricity, high release, and predictable results. Since 1955 our release agents/dry lubricants have performed with the highest efficiency under the most rigorous and technically challenging conditions. This efficiency is a result of higher throughput, less downtime, and lower scrap rates. Applications include lubricating the seals of a sunroof, door, or window and releasing high quality parts with minimal to zero transfer.

MS-143 Series

MS-143 series is a high-performance family of proprietary low molecular weight PTFE products that offer exceptional surface adhesion, low coefficient of friction, and uniform thin film thickness to increase the facility’s throughput. Utilizing water or solvent carriers, they are effective mold release agents for meeting a variety of manufacturing requirements for automotive parts, including electric motor parts. The entire MS-143 series is compatible with most rubbers, plastics, urethanes, and elastomers including door, headlight, and taillight seals.

MS-143 Series Quote

MS-122 Series

MS-122 series utilizes a proprietary fluoropolymer formulation for dry film lubrication/release systems that provides uniform and ultra-thin film coatings while eliminating “slip-stick” and wear. These bondable coatings render higher throughput and less down time due to their advanced release chemistry and durability. They are also effective dry lubricants within the manufacturing plant and seals of the vehicle including window and sunroof seals. All of these aerosolized formulations are also non-flammable.

MS-122 Series Quote

ReleaSys™ Series

ReleaSys™ is our exclusive line of release systems/dry lubricants that provide incredibly thin-film, bondable, and durable coatings to make processes more efficient with lower scrap rates. This efficiency is also a result of higher throughput from no unnecessary steps due to higher quality coatings that do not transfer, are easy to clean, dry/cure faster, and last longer. For example, the ReleaSys 8500 and ReleaSys 7200W are proprietary coatings that are used extensively in automotive applications.

ReleaSys™ Products QuoteSpecialty Aerosols

Miller-Stephenson’s proprietary aerosol products offer exceptional high-quality cleaning solutions that are formulated for the automotive industry with no ODC (ozone-depleting chemicals), no ammonia and are 100% nonflammable with ultra-low odor. Safe to use on automotive windshields, gauges, and cameras.

MS-260

MS-260 is a high-quality cleaner that delivers quick and streak-free cleaning. Excellent for use on many surfaces, particularly for automotive windshields, mirrors, and cameras. MS-260’s fast drying and evaporation property allows for quick and convenient cleaning. It is nonflammable, contains no ammonia, no ODC (ozone-depleting chemicals) and exhibits low global warming potential.

ms-260 QuoteConnector Lubricants

Combining the superior lubricating qualities of Polyphenyl Ether with the cleaning power of a hydrofluoroether azeotrope, Miller-Stephenson has created connector lubricant formulations that provide the most advanced total treatment for connectors. These connector lubricants aid the protection of noble metal connector surfaces from wear, oxidation, and tarnishing. In addition to noble metals, our lubricants are inert to virtually all plastics, metals, and rubbers used in automotive connectors and housings. This wide compatibility eliminates fear of galling and seizing of precious metal connector surfaces. They are non-migrating and do not impede the flow of electrical current through the contacts creating a consistent, reliable electrical connection.

MS Connector Lubricants

MIller-Stephenson’s connector lubricants’ advanced and effective non-migrating qualities make them simple to use and convenient for cleaning. Prevents corrosion and galling on automotive connectors, extending connector life. Formulated to be nonflammable to mitigate fear in high voltage applications. Ideal for electrical harness assemblies. Contact lubricants are also available for moving mechanisms such as switches.

MS-383H/381H: Exceptional connector lubricant for gold, multi-prong connectors. Available as a bulk liquid (383H) or aerosol (381H).

Connector Lubricants QuoteConformal Coatings

Protective conformal coatings are an integral part of today’s sophisticated electronic manufacturing as coating requirements have become more demanding. To meet these needs, Miller-Stephenson’s product line offers a choice of premium conformal coatings, each formulated to meet a specific application requirement. Whether the application calls for a urethane, silicone, acrylic or varnish coating, we have the solution to fulfill these needs. Available in bulk liquid or aerosol packaging.

ShieldSys™ 462S, 470 and 477H

Our premiere conformal coating lines are designed to be highly dependable and long-lasting for automotive applications. They deliver ideal dielectric properties in a “solder-through” even at high temperature and high vibration applications. Provides flexible options with some products formulated specifically to meet MIL-I-46058C Type AR and SR standards. Compatible with delicate component leads and wiring board applications.

Technical SupportCustom Formulations

Since 1955, Miller-Stephenson Chemical Company, Inc. has worked diligently with our customers’ engineers and technicians to optimize formulations for specific manufacturing needs. We can provide custom formulations for mold releases, solvents, lubricants, epoxies, and conformal coatings. Miller-Stephenson offers a dedicated team of engineering specialists and formulation chemists who will work closely with you to help identify your specific manufacturing requirements and provide an optimal solution for your needs.

Didn’t find your specific application?

Automotive is a constantly evolving industry and sometimes the product that is needed, simply does not exist. Miller-Stephenson’s dynamic engineering and research teams can quickly address your application and develop a unique solution. Our experts enjoy the challenge of customizing formulations so that every customer’s manufacturing requirements can be met.

Technical SupportNotwithstanding any express or implied indication to the contrary, product information provided on or via this website is supplied upon the condition that the persons receiving such information will make their own, independent determination as to a given product’s suitability for any contemplated purposes prior to use. In no event will Miller-Stephenson be responsible for damages of any nature whatsoever resulting from the use of, or reliance upon, information provided, directly or indirectly, on this website in relation to any product and/or application.